Каталог Iscar токарный инструмент 2017 - страница 377

Навигация

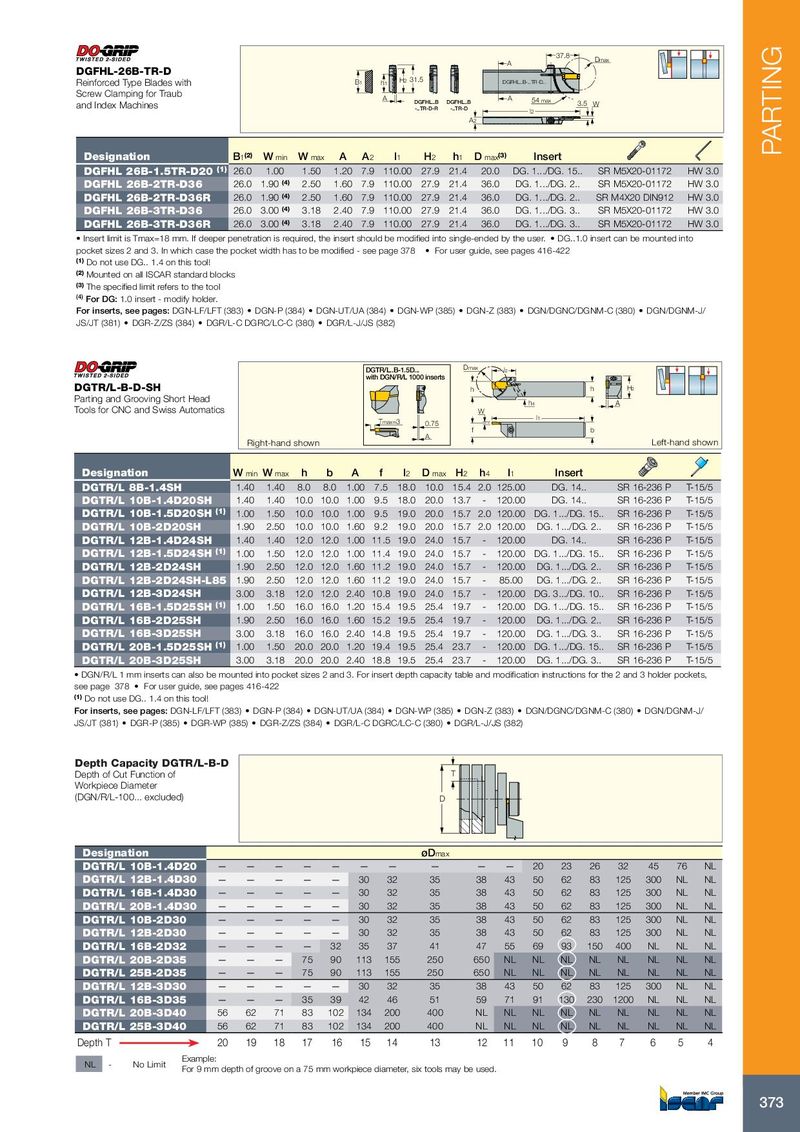

37.8 A Dmax DGFHL-26B-TR-D Reinforced Type Blades with B1 h1 H2 31.5 DGFHL..B-..TR-D.. Screw Clamping for Traub A DGFHL..B DGFHL..B A 54 max and Index Machines 3.5 W -..TR-D-R -..TR-D l2 A2 (3) PARTING Designation B 1 (2) W min W max A A 2 l 1 H 2 h 1 D max Insert DGFHL 26B-1.5TR-D20 (1) 26.0 1.00 1.50 1.20 7.9 110.00 27.9 21.4 20.0 DG. 1.../DG. 15.. SR M5X20-01172 HW 3.0 DGFHL 26B-2TR-D36 26.0 1.90 (4) 2.50 1.60 7.9 110.00 27.9 21.4 36.0 DG. 1.../DG. 2.. SR M5X20-01172 HW 3.0 DGFHL 26B-2TR-D36R 26.0 1.90 (4) 2.50 1.60 7.9 110.00 27.9 21.4 36.0 DG. 1.../DG. 2.. SR M4X20 DIN912 HW 3.0 DGFHL 26B-3TR-D36 26.0 3.00 (4) 3.18 2.40 7.9 110.00 27.9 21.4 36.0 DG. 1.../DG. 3.. SR M5X20-01172 HW 3.0 DGFHL 26B-3TR-D36R 26.0 3.00 (4) 3.18 2.40 7.9 110.00 27.9 21.4 36.0 DG. 1.../DG. 3.. SR M5X20-01172 HW 3.0 • Insert limit is Tmax=18 mm. If deeper penetration is required, the insert should be modified into single-ended by the user. • DG..1.0 insert can be mounted into pocket sizes 2 and 3. In which case the pocket width has to be modified - see page 378 • For user guide, see pages 416-422 (1) Do not use DG.. 1.4 on this tool! (2) Mounted on all ISCAR standard blocks (3) The specified limit refers to the tool (4) For DG: 1.0 insert - modify holder. For inserts, see pages: DGN-LF/LFT (383) • DGN-P (384) • DGN-UT/UA (384) • DGN-WP (385) • DGN-Z (383) • DGN/DGNC/DGNM-C (380) • DGN/DGNM-J/ JS/JT (381) • DGR-Z/ZS (384) • DGR/L-C DGRC/LC-C (380) • DGR/L-J/JS (382) DGTR/L..B-1.5D... Dmax l2 with DGN/R/L 1000 inserts DGTR/L-B-D-SH h h H2 Parting and Grooving Short Head h4 A Tools for CNC and Swiss Automatics W Tmax=3 l1 0.75 f b A Right-hand shown Left-hand shown Designation W min W max h b A f l 2 D max H 2 h 4 l 1 Insert DGTR/L 8B-1.4SH 1.40 1.40 8.0 8.0 1.00 7.5 18.0 10.0 15.4 2.0 125.00 DG. 14.. SR 16-236 P T-15/5 DGTR/L 10B-1.4D20SH 1.40 1.40 10.0 10.0 1.00 9.5 18.0 20.0 13.7 - 120.00 DG. 14.. SR 16-236 P T-15/5 DGTR/L 10B-1.5D20SH (1) 1.00 1.50 10.0 10.0 1.00 9.5 19.0 20.0 15.7 2.0 120.00 DG. 1.../DG. 15.. SR 16-236 P T-15/5 DGTR/L 10B-2D20SH 1.90 2.50 10.0 10.0 1.60 9.2 19.0 20.0 15.7 2.0 120.00 DG. 1.../DG. 2.. SR 16-236 P T-15/5 DGTR/L 12B-1.4D24SH 1.40 1.40 12.0 12.0 1.00 11.5 19.0 24.0 15.7 - 120.00 DG. 14.. SR 16-236 P T-15/5 DGTR/L 12B-1.5D24SH (1) 1.00 1.50 12.0 12.0 1.00 11.4 19.0 24.0 15.7 - 120.00 DG. 1.../DG. 15.. SR 16-236 P T-15/5 DGTR/L 12B-2D24SH 1.90 2.50 12.0 12.0 1.60 11.2 19.0 24.0 15.7 - 120.00 DG. 1.../DG. 2.. SR 16-236 P T-15/5 DGTR/L 12B-2D24SH-L85 1.90 2.50 12.0 12.0 1.60 11.2 19.0 24.0 15.7 - 85.00 DG. 1.../DG. 2.. SR 16-236 P T-15/5 DGTR/L 12B-3D24SH 3.00 3.18 12.0 12.0 2.40 10.8 19.0 24.0 15.7 - 120.00 DG. 3.../DG. 10.. SR 16-236 P T-15/5 DGTR/L 16B-1.5D25SH (1) 1.00 1.50 16.0 16.0 1.20 15.4 19.5 25.4 19.7 - 120.00 DG. 1.../DG. 15.. SR 16-236 P T-15/5 DGTR/L 16B-2D25SH 1.90 2.50 16.0 16.0 1.60 15.2 19.5 25.4 19.7 - 120.00 DG. 1.../DG. 2.. SR 16-236 P T-15/5 DGTR/L 16B-3D25SH 3.00 3.18 16.0 16.0 2.40 14.8 19.5 25.4 19.7 - 120.00 DG. 1.../DG. 3.. SR 16-236 P T-15/5 DGTR/L 20B-1.5D25SH (1) 1.00 1.50 20.0 20.0 1.20 19.4 19.5 25.4 23.7 - 120.00 DG. 1.../DG. 15.. SR 16-236 P T-15/5 DGTR/L 20B-3D25SH 3.00 3.18 20.0 20.0 2.40 18.8 19.5 25.4 23.7 - 120.00 DG. 1.../DG. 3.. SR 16-236 P T-15/5 • DGN/R/L 1 mm inserts can also be mounted into pocket sizes 2 and 3. For insert depth capacity table and modification instructions for the 2 and 3 holder pockets, see page 378 • For user guide, see pages 416-422 (1) Do not use DG.. 1.4 on this tool! For inserts, see pages: DGN-LF/LFT (383) • DGN-P (384) • DGN-UT/UA (384) • DGN-WP (385) • DGN-Z (383) • DGN/DGNC/DGNM-C (380) • DGN/DGNM-J/ JS/JT (381) • DGR-P (385) • DGR-WP (385) • DGR-Z/ZS (384) • DGR/L-C DGRC/LC-C (380) • DGR/L-J/JS (382) Depth Capacity DGTR/L-B-D Depth of Cut Function of T Workpiece Diameter (DGN/R/L-100... excluded) D Designation øD max DGTR/L 10B-1.4D20 — — — — — — — — — — 20 23 26 32 45 76 NL DGTR/L 12B-1.4D30 — — — — — 30 32 35 38 43 50 62 83 125 300 NL NL DGTR/L 16B-1.4D30 — — — — — 30 32 35 38 43 50 62 83 125 300 NL NL DGTR/L 20B-1.4D30 — — — — — 30 32 35 38 43 50 62 83 125 300 NL NL DGTR/L 10B-2D30 — — — — — 30 32 35 38 43 50 62 83 125 300 NL NL DGTR/L 12B-2D30 — — — — — 30 32 35 38 43 50 62 83 125 300 NL NL DGTR/L 16B-2D32 — — — — 32 35 37 41 47 55 69 93 150 400 NL NL NL DGTR/L 20B-2D35 — — — 75 90 113 155 250 650 NL NL NL NL NL NL NL NL DGTR/L 25B-2D35 — — — 75 90 113 155 250 650 NL NL NL NL NL NL NL NL DGTR/L 12B-3D30 — — — — — 30 32 35 38 43 50 62 83 125 300 NL NL DGTR/L 16B-3D35 — — — 35 39 42 46 51 59 71 91 130 230 1200 NL NL NL DGTR/L 20B-3D40 56 62 71 83 102 134 200 400 NL NL NL NL NL NL NL NL NL DGTR/L 25B-3D40 56 62 71 83 102 134 200 400 NL NL NL NL NL NL NL NL NL Depth T 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 Example: NL - No Limit For 9 mm depth of groove on a 75 mm workpiece diameter, six tools may be used. 373

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017