Каталог Iscar токарный инструмент 2017 - страница 352

Навигация

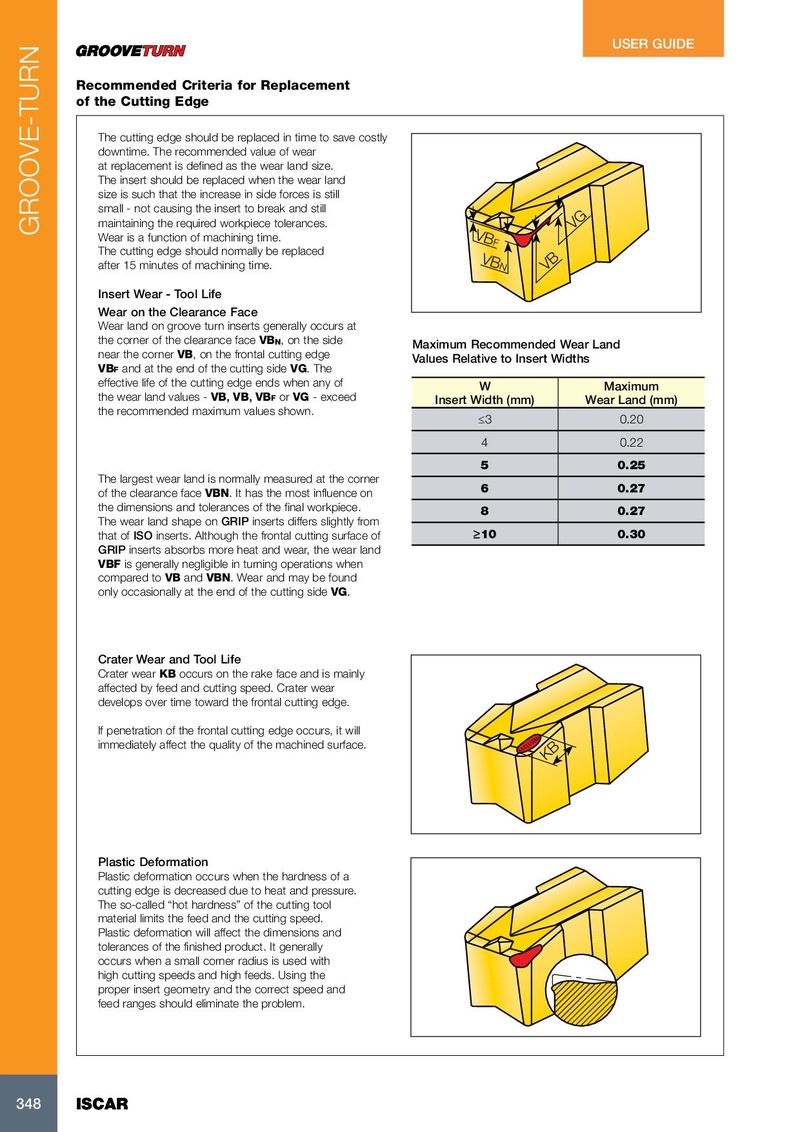

USER GUIDE Recommended Criteria for Replacement of the Cutting Edge The cutting edge should be replaced in time to save costly downtime. The recommended value of wear at replacement is defined as the wear land size. The insert should be replaced when the wear land size is such that the increase in side forces is still small - not causing the insert to break and still maintaining the required workpiece tolerances. VG GROOVE-TURN Wear is a function of machining time. V B F The cutting edge should normally be replaced VB after 15 minutes of machining time. N VB Insert Wear - Tool Life Wear on the Clearance Face Wear land on groove turn inserts generally occurs at the corner of the clearance face VB N , on the side Maximum Recommended Wear Land near the corner VB, on the frontal cutting edge Values Relative to Insert Widths VB F and at the end of the cutting side VG. The effective life of the cutting edge ends when any of W Maximum the wear land values - VB, VB, VB F or VG - exceed Insert Width (mm) Wear Land (mm) the recommended maximum values shown. ≤3 0.20 4 0.22 5 0.25 The largest wear land is normally measured at the corner 6 0.27 of the clearance face VBN. It has the most influence on the dimensions and tolerances of the final workpiece. 8 0.27 The wear land shape on GRIP inserts differs slightly from that of ISO inserts. Although the frontal cutting surface of ≥10 0.30 GRIP inserts absorbs more heat and wear, the wear land VBF is generally negligible in turning operations when compared to VB and VBN. Wear and may be found only occasionally at the end of the cutting side VG. Crater Wear and Tool Life Crater wear KB occurs on the rake face and is mainly affected by feed and cutting speed. Crater wear develops over time toward the frontal cutting edge. If penetration of the frontal cutting edge occurs, it will immediately affect the quality of the machined surface. KB Plastic Deformation Plastic deformation occurs when the hardness of a cutting edge is decreased due to heat and pressure. The so-called “hot hardness” of the cutting tool material limits the feed and the cutting speed. Plastic deformation will affect the dimensions and tolerances of the finished product. It generally occurs when a small corner radius is used with high cutting speeds and high feeds. Using the proper insert geometry and the correct speed and feed ranges should eliminate the problem. 348 348 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017