Каталог Iscar токарный инструмент 2017 - страница 349

Навигация

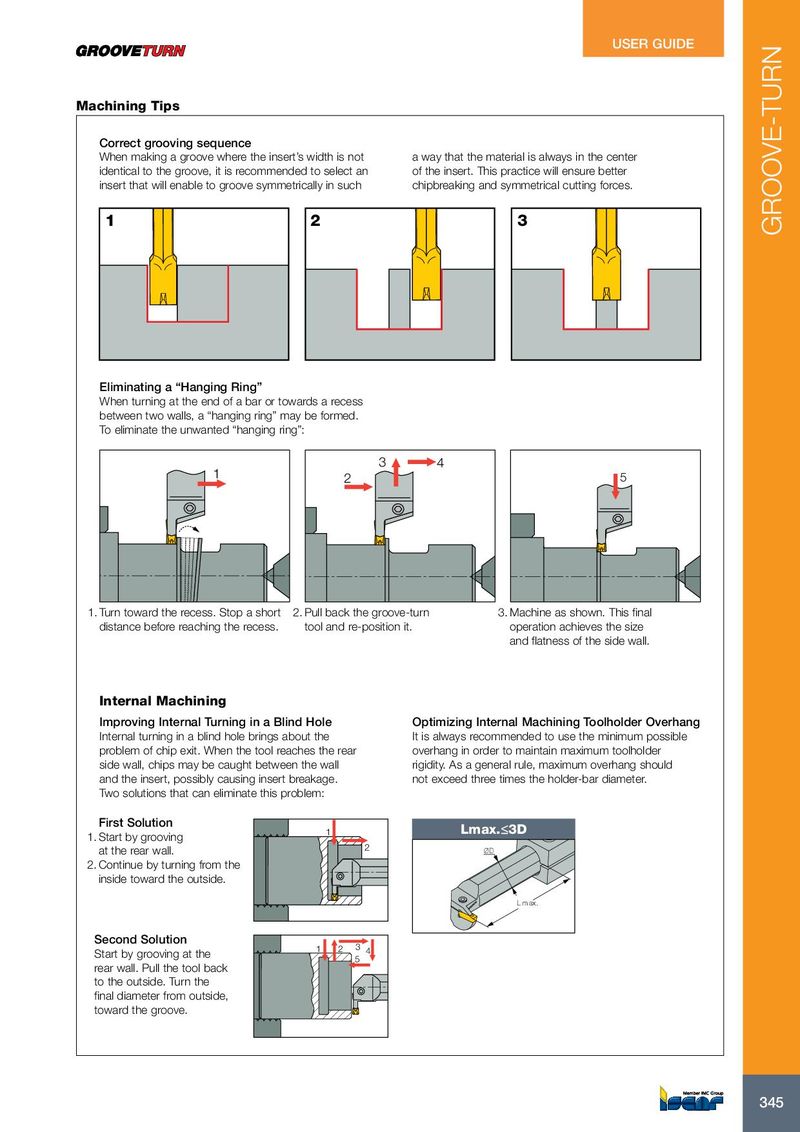

USER GUIDE Machining Tips Correct grooving sequence When making a groove where the insert’s width is not a way that the material is always in the center identical to the groove, it is recommended to select an of the insert. This practice will ensure better insert that will enable to groove symmetrically in such chipbreaking and symmetrical cutting forces. 1 2 3 GROOVE-TURN Eliminating a “Hanging Ring” When turning at the end of a bar or towards a recess between two walls, a “hanging ring” may be formed. To eliminate the unwanted “hanging ring”: 3 4 1 2 5 1. Turn toward the recess. Stop a short 2. Pull back the groove-turn 3. Machine as shown. This final distance before reaching the recess. tool and re-position it. operation achieves the size and flatness of the side wall. Internal Machining Improving Internal Turning in a Blind Hole Optimizing Internal Machining Toolholder Overhang Internal turning in a blind hole brings about the It is always recommended to use the minimum possible problem of chip exit. When the tool reaches the rear overhang in order to maintain maximum toolholder side wall, chips may be caught between the wall rigidity. As a general rule, maximum overhang should and the insert, possibly causing insert breakage. not exceed three times the holder-bar diameter. Two solutions that can eliminate this problem: First Solution 1 Lmax.≤3D 1. Start by grooving 2 at the rear wall. ØD 2. Continue by turning from the inside toward the outside. L max. Second Solution 1 2 3 Start by grooving at the 4 5 rear wall. Pull the tool back to the outside. Turn the final diameter from outside, toward the groove. 345 345

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017