Каталог Iscar токарный инструмент 2017 - страница 347

Навигация

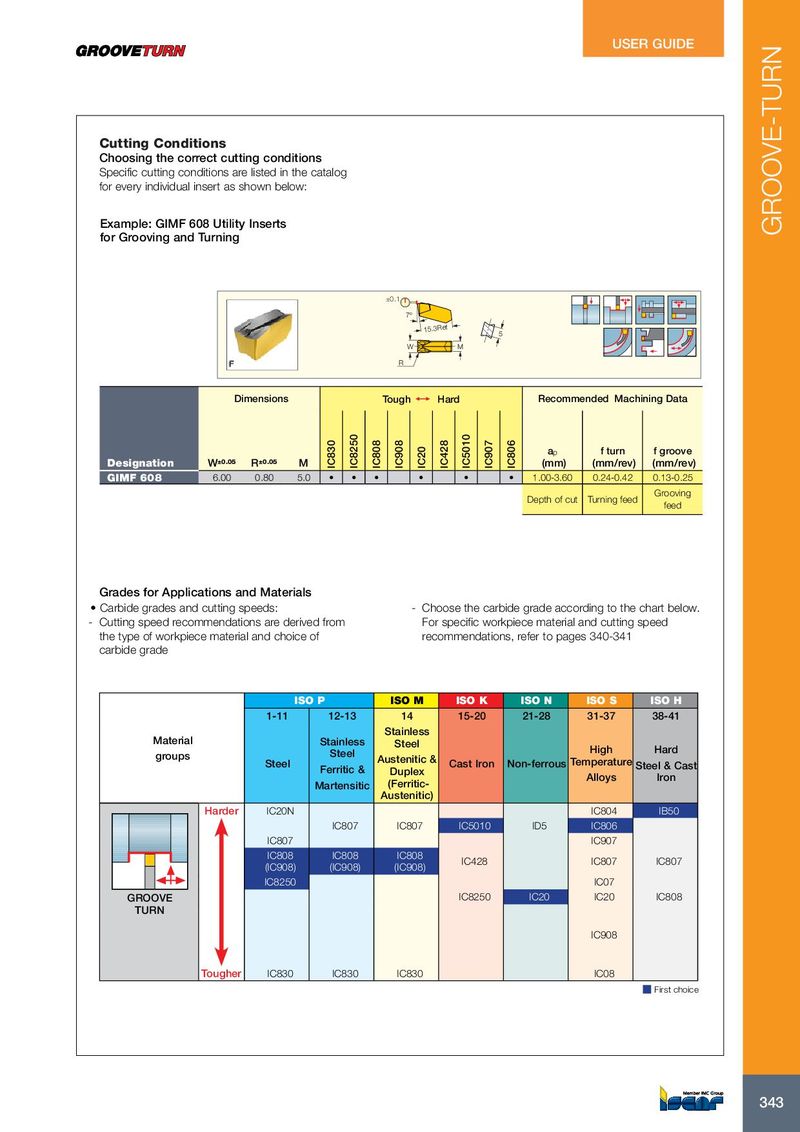

USER GUIDE Cutting Conditions Choosing the correct cutting conditions Specific cutting conditions are listed in the catalog for every individual insert as shown below: Example: GIMF 608 Utility Inserts GROOVE-TURN for Grooving and Turning ±0.1 7º 15.3Ref 5 W M R Dimensions Tough 1 Hard Recommended Machining Data a p f turn f groove Designation W ±0.05 R ±0.05 M IC830 IC8250 IC808 IC908 IC20 IC428 IC5010 IC907 IC806 (mm) (mm/rev) (mm/rev) GIMF 608 6.00 0.80 5.0 • • • • • • 1.00-3.60 0.24-0.42 0.13-0.25 Grooving Depth of cut Turning feed feed Grades for Applications and Materials • Carbide grades and cutting speeds: - Choose the carbide grade according to the chart below. - Cutting speed recommendations are derived from For specific workpiece material and cutting speed the type of workpiece material and choice of recommendations, refer to pages 340-341 carbide grade ISO P ISO M ISO K ISO N ISO S ISO H 1-11 12-13 14 15-20 21-28 31-37 38-41 Stainless Material Stainless Steel High Hard groups Steel Austenitic & Steel Cast Iron Non-ferrous Temperature Steel & Cast Ferritic & Duplex Alloys Iron Martensitic (Ferritic- Austenitic) Harder IC20N IC804 IB50 IC807 IC807 IC5010 ID5 IC806 IC807 IC907 IC808 IC808 IC808 IC428 IC807 IC807 (IC908) (IC908) (IC908) IC8250 IC07 GROOVE IC8250 IC20 IC20 IC808 TURN IC908 Tougher IC830 IC830 IC830 IC08 First choice 343 343

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017