Каталог Iscar токарный инструмент 2017 - страница 346

Навигация

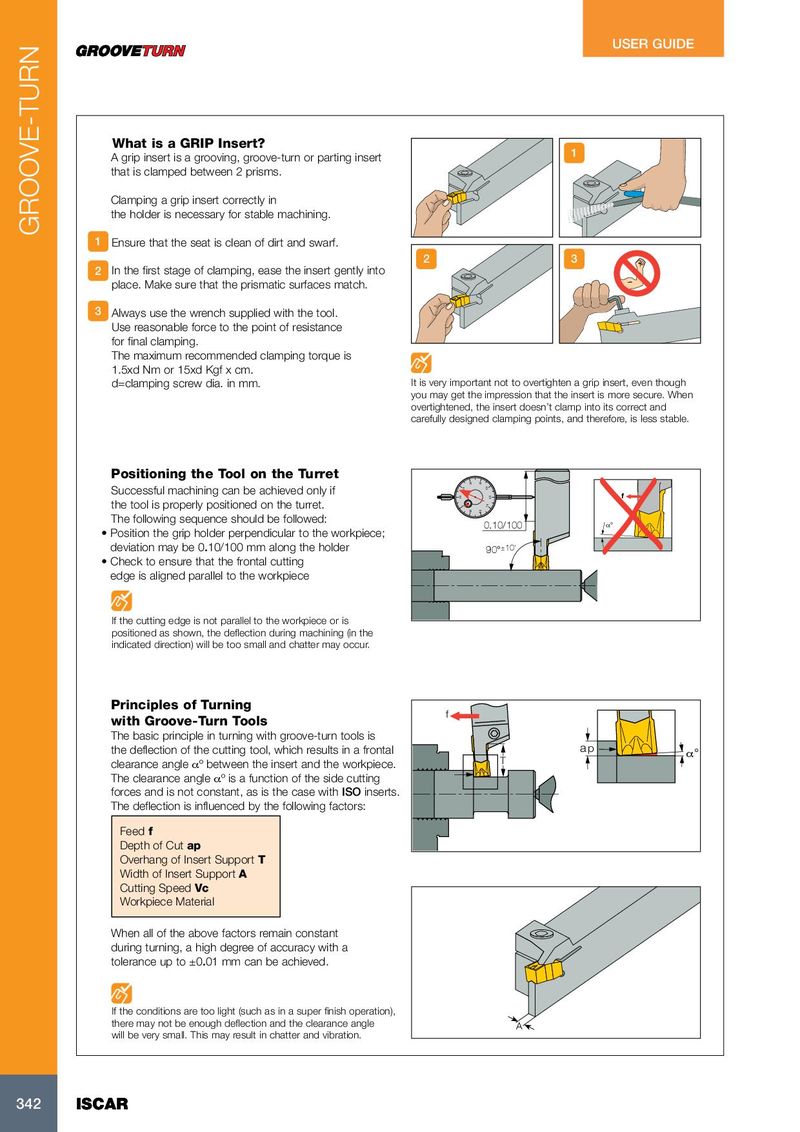

USER GUIDE What is a GRIP Insert? 1 A grip insert is a grooving, groove-turn or parting insert that is clamped between 2 prisms. Clamping a grip insert correctly in the holder is necessary for stable machining. GROOVE-TURN 1 • Ensure that the seat is clean of dirt and swarf. 2 3 2 • In the first stage of clamping, ease the insert gently into place. Make sure that the prismatic surfaces match. 3 • Always use the wrench supplied with the tool. Use reasonable force to the point of resistance for final clamping. The maximum recommended clamping torque is 1.5xd Nm or 15xd Kgf x cm. d=clamping screw dia. in mm. It is very important not to overtighten a grip insert, even though you may get the impression that the insert is more secure. When overtightened, the insert doesn’t clamp into its correct and carefully designed clamping points, and therefore, is less stable. Positioning the Tool on the Turret 30 40 20 50 Successful machining can be achieved only if 10 60 f the tool is properly positioned on the turret. 0 70 90 80 The following sequence should be followed: 0.10/100 α° • Position the grip holder perpendicular to the workpiece; deviation may be 0.10/100 mm along the holder 90° ±10' • Check to ensure that the frontal cutting edge is aligned parallel to the workpiece If the cutting edge is not parallel to the workpiece or is positioned as shown, the deflection during machining (in the indicated direction) will be too small and chatter may occur. Principles of Turning f with Groove-Turn Tools The basic principle in turning with groove-turn tools is the deflection of the cutting tool, which results in a frontal ap α° clearance angle αº between the insert and the workpiece. T The clearance angle αº is a function of the side cutting forces and is not constant, as is the case with ISO inserts. The deflection is influenced by the following factors: Feed f Depth of Cut ap Overhang of Insert Support T Width of Insert Support A Cutting Speed Vc Workpiece Material When all of the above factors remain constant during turning, a high degree of accuracy with a tolerance up to ±0.01 mm can be achieved. If the conditions are too light (such as in a super finish operation), there may not be enough deflection and the clearance angle A will be very small. This may result in chatter and vibration. 342 342 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017