Каталог Iscar токарный инструмент 2017 - страница 316

Навигация

l1

l2

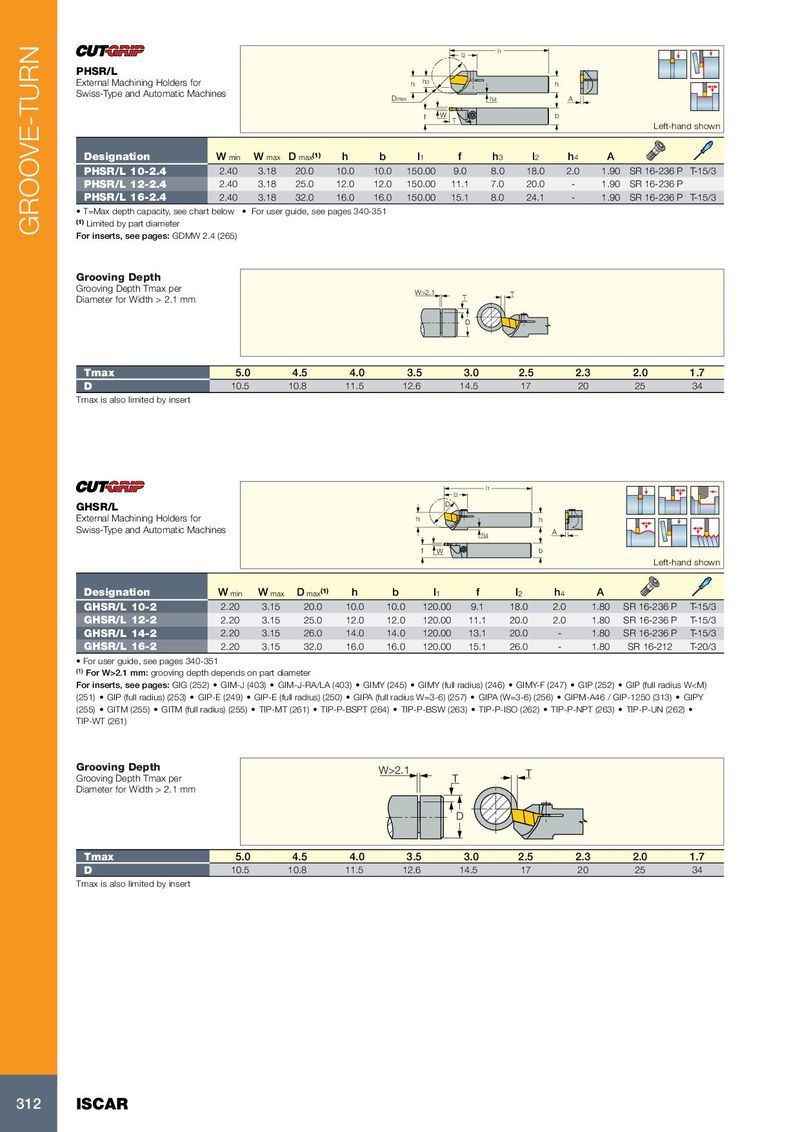

PHSR/L

External Machining Holders for h h3 h

Swiss-Type and Automatic Machines Dmax h4 A

f W b

T

Left-hand shown

Designation W min W max D max (1) h b l 1 f h 3 l 2 h 4 A

PHSR/L 10-2.4 2.40 3.18 20.0 10.0 10.0 150.00 9.0 8.0 18.0 2.0 1.90 SR 16-236 P T-15/3

PHSR/L 12-2.4 2.40 3.18 25.0 12.0 12.0 150.00 11.1 7.0 20.0 - 1.90 SR 16-236 P

PHSR/L 16-2.4 2.40 3.18 32.0 16.0 16.0 150.00 15.1 8.0 24.1 - 1.90 SR 16-236 P T-15/3

• T=Max depth capacity, see chart below • For user guide, see pages 340-351

(1) Limited by part diameter

GROOVE-TURN For inserts, see pages: GDMW 2.4 (265)

Grooving Depth

Grooving Depth Tmax per W>2.1

Diameter for Width > 2.1 mm T T

D

Tmax 5.0 4.5 4.0 3.5 3.0 2.5 2.3 2.0 1.7

D 10.5 10.8 11.5 12.6 14.5 17 20 25 34

Tmax is also limited by insert

l1

l2

D

GHSR/L

External Machining Holders for h h

Swiss-Type and Automatic Machines

h4 A

f W b

Left-hand shown

Designation W min W max D max (1) h b l 1 f l 2 h 4 A

GHSR/L 10-2 2.20 3.15 20.0 10.0 10.0 120.00 9.1 18.0 2.0 1.80 SR 16-236 P T-15/3

GHSR/L 12-2 2.20 3.15 25.0 12.0 12.0 120.00 11.1 20.0 2.0 1.80 SR 16-236 P T-15/3

GHSR/L 14-2 2.20 3.15 26.0 14.0 14.0 120.00 13.1 20.0 - 1.80 SR 16-236 P T-15/3

GHSR/L 16-2 2.20 3.15 32.0 16.0 16.0 120.00 15.1 26.0 - 1.80 SR 16-212 T-20/3

• For user guide, see pages 340-351

(1) For W>2.1 mm: grooving depth depends on part diameter

For inserts, see pages: GIG (252) • GIM-J (403) • GIM-J-RA/LA (403) • GIMY (245) • GIMY (full radius) (246) • GIMY-F (247) • GIP (252) • GIP (full radius W

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017