Каталог Iscar токарный инструмент 2017 - страница 312

Навигация

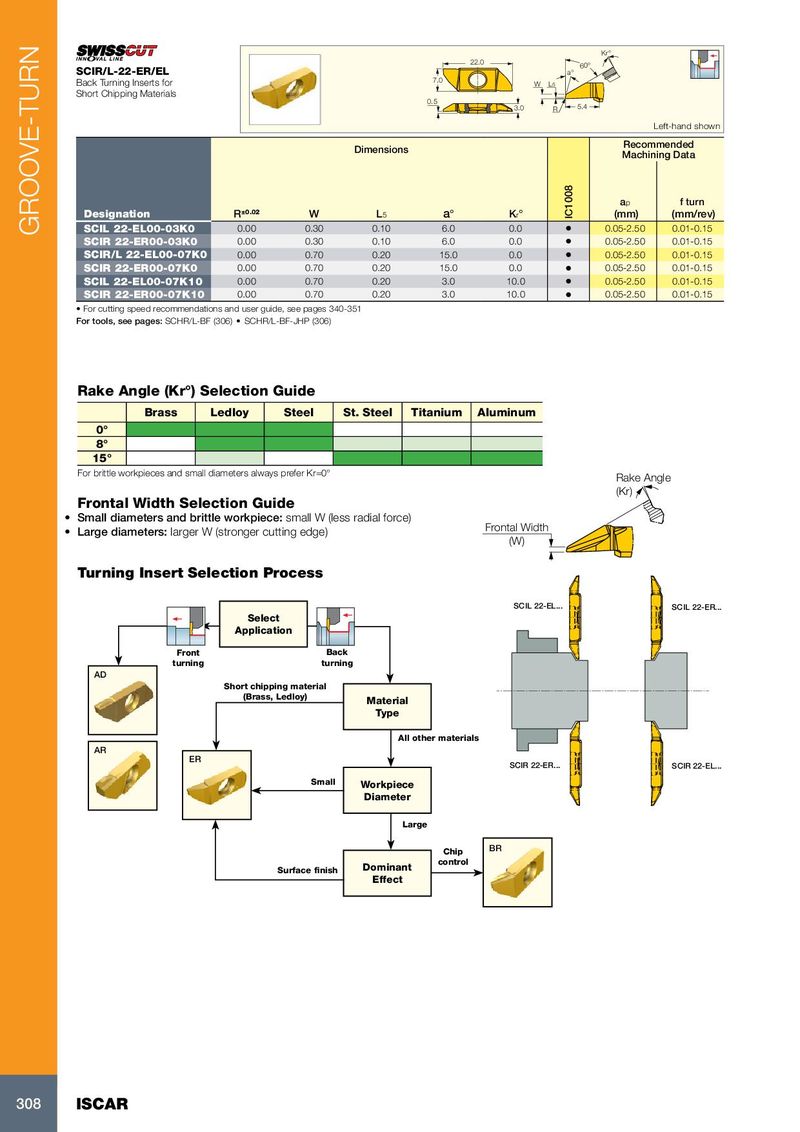

Kr° 22.0 60° SCIR/L-22-ER/EL a° Back Turning Inserts for 7.0 W L5 Short Chipping Materials 0.5 3.0 R 5.4 Left-hand shown Recommended Dimensions Machining Data a p f turn Designation R ±0.02 W L 5 a° K r ° IC1008 (mm) (mm/rev) GROOVE-TURN SCIL 22-EL00-03K0 0.00 0.30 0.10 6.0 0.0 • 0.05-2.50 0.01-0.15 SCIR 22-ER00-03K0 0.00 0.30 0.10 6.0 0.0 • 0.05-2.50 0.01-0.15 SCIR/L 22-EL00-07K0 0.00 0.70 0.20 15.0 0.0 • 0.05-2.50 0.01-0.15 SCIR 22-ER00-07K0 0.00 0.70 0.20 15.0 0.0 • 0.05-2.50 0.01-0.15 SCIL 22-EL00-07K10 0.00 0.70 0.20 3.0 10.0 • 0.05-2.50 0.01-0.15 SCIR 22-ER00-07K10 0.00 0.70 0.20 3.0 10.0 • 0.05-2.50 0.01-0.15 • For cutting speed recommendations and user guide, see pages 340-351 For tools, see pages: SCHR/L-BF (306) • SCHR/L-BF-JHP (306) Rake Angle (Kr°) Selection Guide Brass Ledloy Steel St. Steel Titanium Aluminum 0° 8° 15° For brittle workpieces and small diameters always prefer Kr=0° Rake Angle (Kr) Frontal Width Selection Guide • Small diameters and brittle workpiece: small W (less radial force) Frontal Width • Large diameters: larger W (stronger cutting edge) (W) Turning Insert Selection Process SCIL 22-EL... SCIL 22-ER... Select Application Front Back turning turning AD Short chipping material (Brass, Ledloy) Material Type All other materials AR ER SCIR 22-ER... SCIR 22-EL... Small Workpiece Diameter Large Chip BR control Surface finish Dominant Effect 308 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017