Каталог Iscar токарный инструмент 2017 - страница 307

Навигация

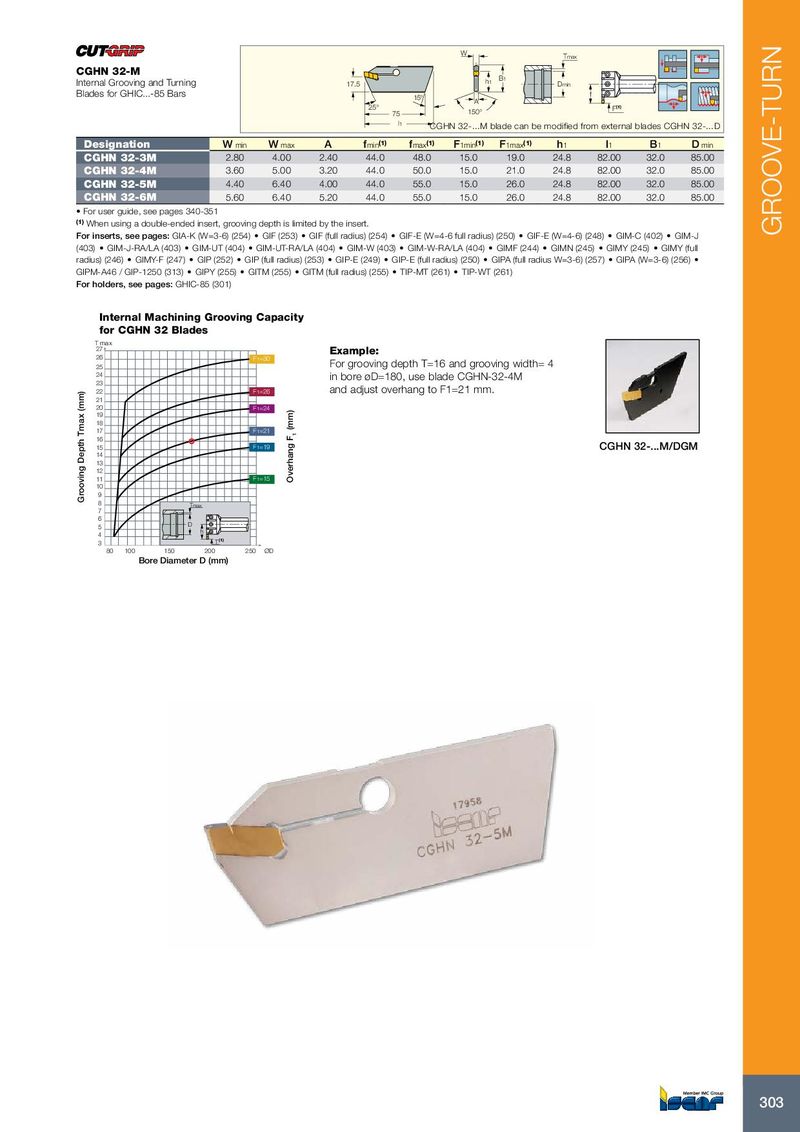

W Tmax CGHN 32-M Internal Grooving and Turning 17.5 h1 B1 Dmin Blades for GHIC...-85 Bars 15° f A 25° 150° F (1) 75 l1 CGHN 32-...M blade can be modified from external blades CGHN 32-...D Designation W min W max A f min (1) f max (1) F 1min (1) F 1max (1) h 1 l 1 B 1 D min CGHN 32-3M 2.80 4.00 2.40 44.0 48.0 15.0 19.0 24.8 82.00 32.0 85.00 CGHN 32-4M 3.60 5.00 3.20 44.0 50.0 15.0 21.0 24.8 82.00 32.0 85.00 CGHN 32-5M 4.40 6.40 4.00 44.0 55.0 15.0 26.0 24.8 82.00 32.0 85.00 CGHN 32-6M 5.60 6.40 5.20 44.0 55.0 15.0 26.0 24.8 82.00 32.0 85.00 • For user guide, see pages 340-351 (1) When using a double-ended insert, grooving depth is limited by the insert. For inserts, see pages: GIA-K (W=3-6) (254) • GIF (253) • GIF (full radius) (254) • GIF-E (W=4-6 full radius) (250) • GIF-E (W=4-6) (248) • GIM-C (402) • GIM-J GROOVE-TURN (403) • GIM-J-RA/LA (403) • GIM-UT (404) • GIM-UT-RA/LA (404) • GIM-W (403) • GIM-W-RA/LA (404) • GIMF (244) • GIMN (245) • GIMY (245) • GIMY (full radius) (246) • GIMY-F (247) • GIP (252) • GIP (full radius) (253) • GIP-E (249) • GIP-E (full radius) (250) • GIPA (full radius W=3-6) (257) • GIPA (W=3-6) (256) • GIPM-A46 / GIP-1250 (313) • GIPY (255) • GITM (255) • GITM (full radius) (255) • TIP-MT (261) • TIP-WT (261) For holders, see pages: GHIC-85 (301) Internal Machining Grooving Capacity for CGHN 32 Blades T max 27 Example: 26 F1=30 25 For grooving depth T=16 and grooving width= 4 24 in bore øD=180, use blade CGHN-32-4M 23 22 F1=26 and adjust overhang to F1=21 mm. 21 20 F1=24 19 18 17 F1=21 (mm) 1 16 15 F1=19 CGHN 32-...M/DGM 14 13 12 11 F1=15 Overhang F 10 9 Grooving Depth Tmax (mm) 8 Tmax 7 6 5 D 4 f1 3 T (1) 80 100 150 200 250 ØD Bore Diameter D (mm) 303

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017