Каталог Iscar токарный инструмент 2017 - страница 305

Навигация

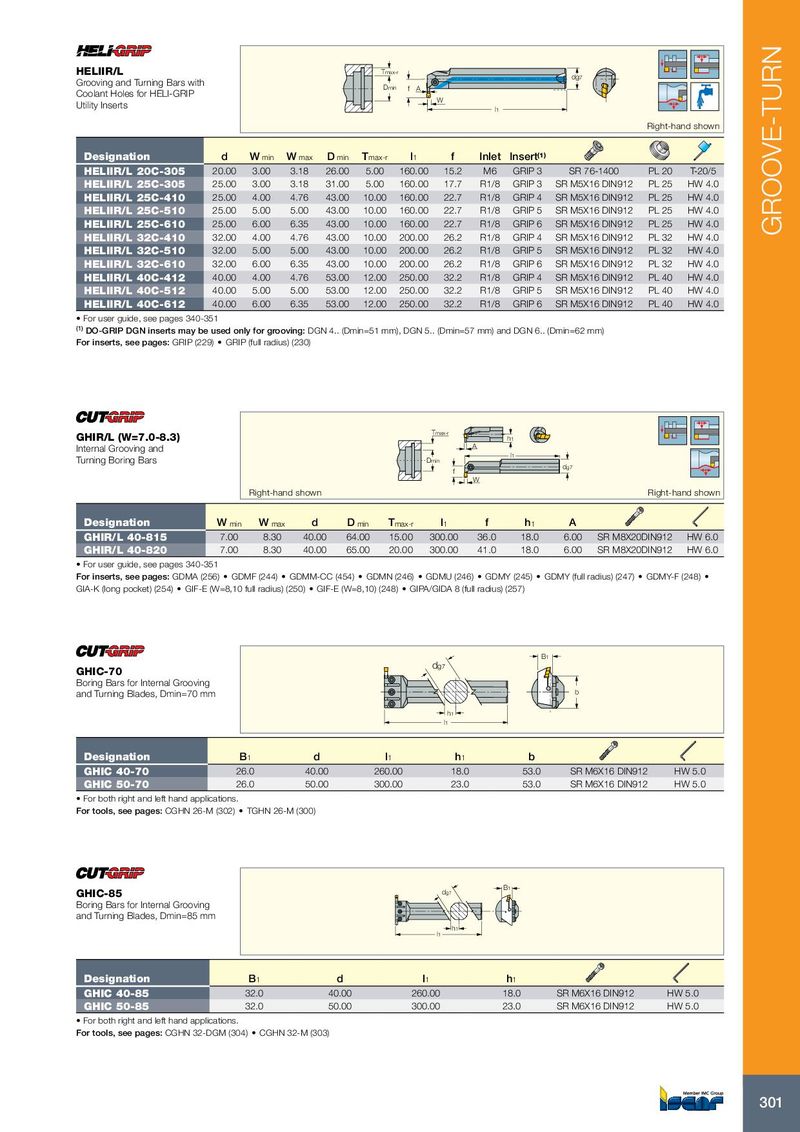

HELIIR/L Tmax-r dg7 Grooving and Turning Bars with Dmin f A Coolant Holes for HELI-GRIP W Utility Inserts l1 Right-hand shown Designation d W min W max D min T max-r l 1 f Inlet Insert (1) HELIIR/L 20C-305 20.00 3.00 3.18 26.00 5.00 160.00 15.2 M6 GRIP 3 SR 76-1400 PL 20 T-20/5 HELIIR/L 25C-305 25.00 3.00 3.18 31.00 5.00 160.00 17.7 R1/8 GRIP 3 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 25C-410 25.00 4.00 4.76 43.00 10.00 160.00 22.7 R1/8 GRIP 4 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 25C-510 25.00 5.00 5.00 43.00 10.00 160.00 22.7 R1/8 GRIP 5 SR M5X16 DIN912 PL 25 HW 4.0 HELIIR/L 25C-610 25.00 6.00 6.35 43.00 10.00 160.00 22.7 R1/8 GRIP 6 SR M5X16 DIN912 PL 25 HW 4.0 GROOVE-TURN HELIIR/L 32C-410 32.00 4.00 4.76 43.00 10.00 200.00 26.2 R1/8 GRIP 4 SR M5X16 DIN912 PL 32 HW 4.0 HELIIR/L 32C-510 32.00 5.00 5.00 43.00 10.00 200.00 26.2 R1/8 GRIP 5 SR M5X16 DIN912 PL 32 HW 4.0 HELIIR/L 32C-610 32.00 6.00 6.35 43.00 10.00 200.00 26.2 R1/8 GRIP 6 SR M5X16 DIN912 PL 32 HW 4.0 HELIIR/L 40C-412 40.00 4.00 4.76 53.00 12.00 250.00 32.2 R1/8 GRIP 4 SR M5X16 DIN912 PL 40 HW 4.0 HELIIR/L 40C-512 40.00 5.00 5.00 53.00 12.00 250.00 32.2 R1/8 GRIP 5 SR M5X16 DIN912 PL 40 HW 4.0 HELIIR/L 40C-612 40.00 6.00 6.35 53.00 12.00 250.00 32.2 R1/8 GRIP 6 SR M5X16 DIN912 PL 40 HW 4.0 • For user guide, see pages 340-351 (1) DO-GRIP DGN inserts may be used only for grooving: DGN 4.. (Dmin=51 mm), DGN 5.. (Dmin=57 mm) and DGN 6.. (Dmin=62 mm) For inserts, see pages: GRIP (229) • GRIP (full radius) (230) Tmax-r GHIR/L (W=7.0-8.3) h1 Internal Grooving and A l1 Turning Boring Bars Dmin dg7 f W Right-hand shown Right-hand shown Designation W min W max d D min T max-r l 1 f h 1 A GHIR/L 40-815 7.00 8.30 40.00 64.00 15.00 300.00 36.0 18.0 6.00 SR M8X20DIN912 HW 6.0 GHIR/L 40-820 7.00 8.30 40.00 65.00 20.00 300.00 41.0 18.0 6.00 SR M8X20DIN912 HW 6.0 • For user guide, see pages 340-351 For inserts, see pages: GDMA (256) • GDMF (244) • GDMM-CC (454) • GDMN (246) • GDMU (246) • GDMY (245) • GDMY (full radius) (247) • GDMY-F (248) • GIA-K (long pocket) (254) • GIF-E (W=8,10 full radius) (250) • GIF-E (W=8,10) (248) • GIPA/GIDA 8 (full radius) (257) B1 dg7 GHIC-70 Boring Bars for Internal Grooving and Turning Blades, Dmin=70 mm b h1 l1 Designation B 1 d l 1 h 1 b GHIC 40-70 26.0 40.00 260.00 18.0 53.0 SR M6X16 DIN912 HW 5.0 GHIC 50-70 26.0 50.00 300.00 23.0 53.0 SR M6X16 DIN912 HW 5.0 • For both right and left hand applications. For tools, see pages: CGHN 26-M (302) • TGHN 26-M (300) B1 GHIC-85 dg7 Boring Bars for Internal Grooving and Turning Blades, Dmin=85 mm h1 l1 Designation B 1 d l 1 h 1 GHIC 40-85 32.0 40.00 260.00 18.0 SR M6X16 DIN912 HW 5.0 GHIC 50-85 32.0 50.00 300.00 23.0 SR M6X16 DIN912 HW 5.0 • For both right and left hand applications. For tools, see pages: CGHN 32-DGM (304) • CGHN 32-M (303) 301

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017