Каталог Iscar токарный инструмент 2017 - страница 260

Навигация

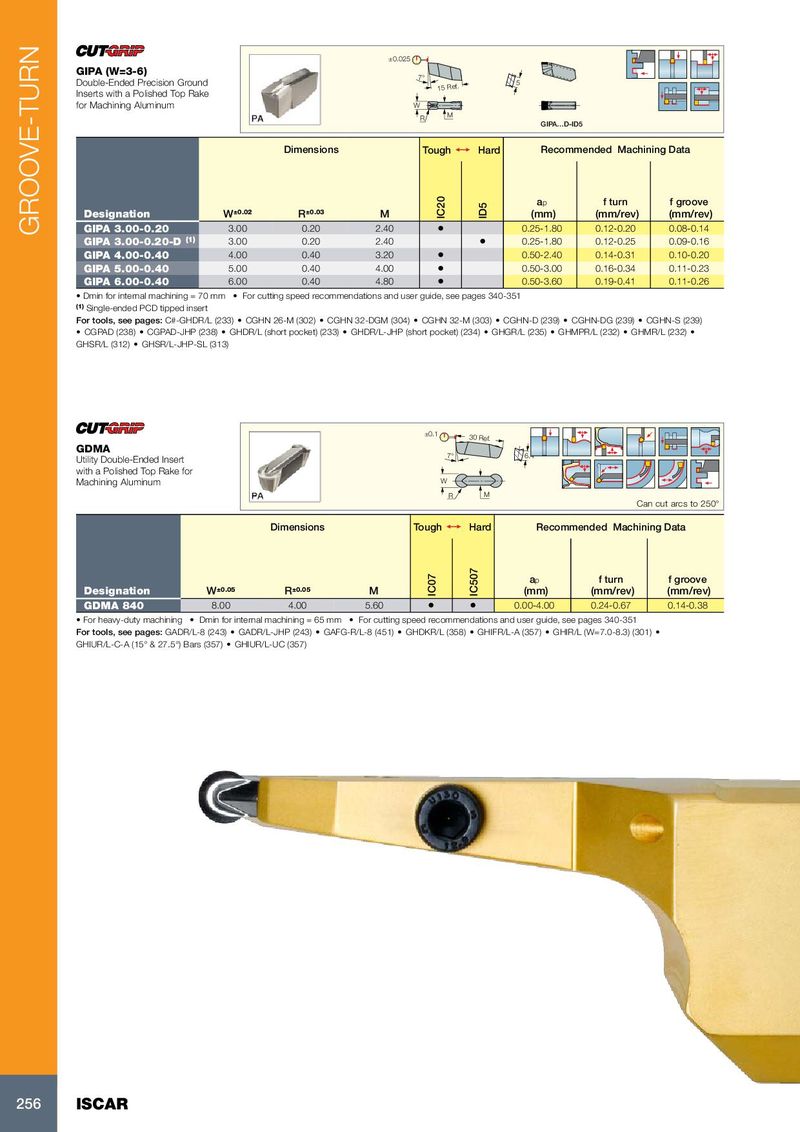

±0.025 GIPA (W=3-6) 7° Double-Ended Precision Ground 5 15 Ref. Inserts with a Polished Top Rake for Machining Aluminum W R M GIPA…D-ID5 Dimensions Tough 1 Hard Recommended Machining Data a p f turn f groove Designation W ±0.02 R ±0.03 M IC20 ID5 (mm) (mm/rev) (mm/rev) 3.00 0.20 2.40 GROOVE-TURN GIPA 3.00-0.20 • 0.25-1.80 0.12-0.20 0.08-0.14 GIPA 3.00-0.20-D (1) 3.00 0.20 2.40 • 0.25-1.80 0.12-0.25 0.09-0.16 GIPA 4.00-0.40 4.00 0.40 3.20 • 0.50-2.40 0.14-0.31 0.10-0.20 GIPA 5.00-0.40 5.00 0.40 4.00 • 0.50-3.00 0.16-0.34 0.11-0.23 GIPA 6.00-0.40 6.00 0.40 4.80 • 0.50-3.60 0.19-0.41 0.11-0.26 • Dmin for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 340-351 (1) Single-ended PCD tipped insert For tools, see pages: C#-GHDR/L (233) • CGHN 26-M (302) • CGHN 32-DGM (304) • CGHN 32-M (303) • CGHN-D (239) • CGHN-DG (239) • CGHN-S (239) • CGPAD (238) • CGPAD-JHP (238) • GHDR/L (short pocket) (233) • GHDR/L-JHP (short pocket) (234) • GHGR/L (235) • GHMPR/L (232) • GHMR/L (232) • GHSR/L (312) • GHSR/L-JHP-SL (313) ±0.1 30 Ref. GDMA 7° 6.4 Utility Double-Ended Insert with a Polished Top Rake for Machining Aluminum W R M Can cut arcs to 250° Dimensions Tough 1 Hard Recommended Machining Data a p f turn f groove Designation W ±0.05 R ±0.05 M IC07 IC507 (mm) (mm/rev) (mm/rev) GDMA 840 8.00 4.00 5.60 • • 0.00-4.00 0.24-0.67 0.14-0.38 • For heavy-duty machining • Dmin for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 340-351 For tools, see pages: GADR/L-8 (243) • GADR/L-JHP (243) • GAFG-R/L-8 (451) • GHDKR/L (358) • GHIFR/L-A (357) • GHIR/L (W=7.0-8.3) (301) • GHIUR/L-C-A (15° & 27.5°) Bars (357) • GHIUR/L-UC (357) 256 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017