Каталог Iscar токарный инструмент 2017 - страница 239

Навигация

l2

Dmax

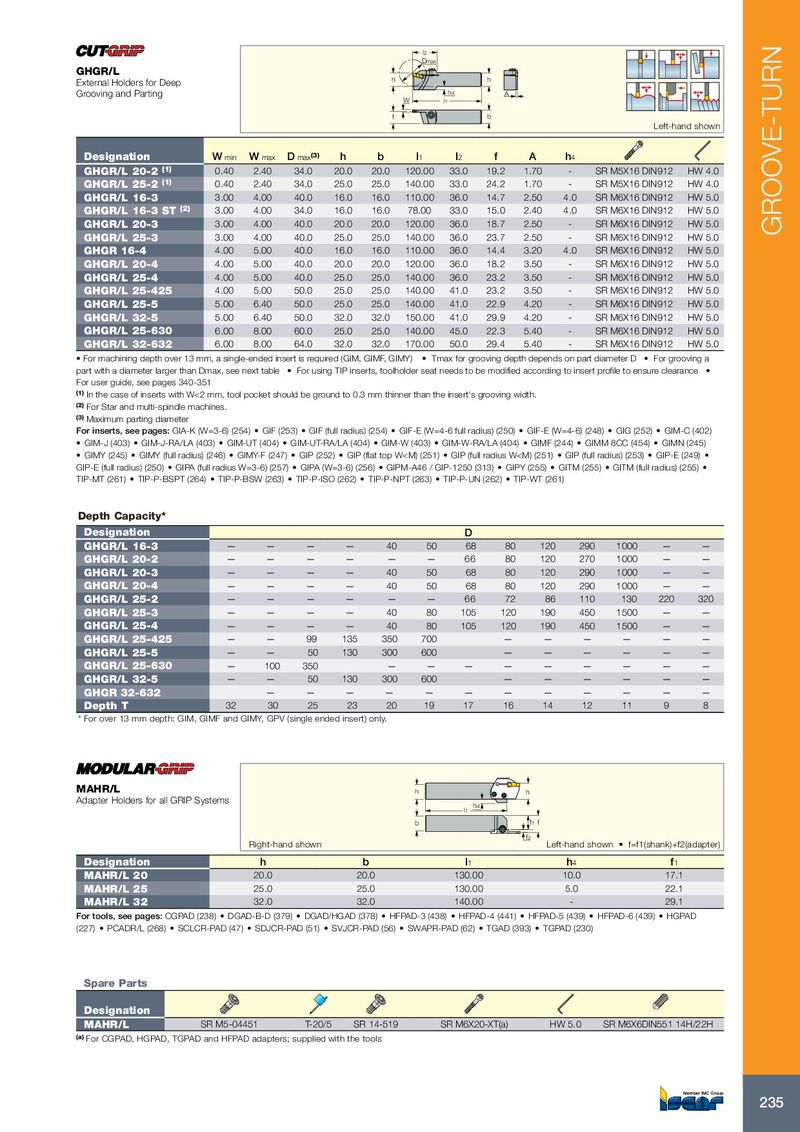

GHGR/L

External Holders for Deep h h

Grooving and Parting h4 A

W l1

f b

Left-hand shown

Designation W min W max D max (3) h b l 1 l 2 f A h 4

GHGR/L 20-2 (1) 0.40 2.40 34.0 20.0 20.0 120.00 33.0 19.2 1.70 - SR M5X16 DIN912 HW 4.0

GHGR/L 25-2 (1) 0.40 2.40 34.0 25.0 25.0 140.00 33.0 24.2 1.70 - SR M5X16 DIN912 HW 4.0

GHGR/L 16-3 3.00 4.00 40.0 16.0 16.0 110.00 36.0 14.7 2.50 4.0 SR M6X16 DIN912 HW 5.0

GHGR/L 16-3 ST (2) 3.00 4.00 34.0 16.0 16.0 78.00 33.0 15.0 2.40 4.0 SR M6X16 DIN912 HW 5.0

GHGR/L 20-3 3.00 4.00 40.0 20.0 20.0 120.00 36.0 18.7 2.50 - SR M6X16 DIN912 HW 5.0

GROOVE-TURN

GHGR/L 25-3 3.00 4.00 40.0 25.0 25.0 140.00 36.0 23.7 2.50 - SR M6X16 DIN912 HW 5.0

GHGR 16-4 4.00 5.00 40.0 16.0 16.0 110.00 36.0 14.4 3.20 4.0 SR M6X16 DIN912 HW 5.0

GHGR/L 20-4 4.00 5.00 40.0 20.0 20.0 120.00 36.0 18.2 3.50 - SR M6X16 DIN912 HW 5.0

GHGR/L 25-4 4.00 5.00 40.0 25.0 25.0 140.00 36.0 23.2 3.50 - SR M6X16 DIN912 HW 5.0

GHGR/L 25-425 4.00 5.00 50.0 25.0 25.0 140.00 41.0 23.2 3.50 - SR M6X16 DIN912 HW 5.0

GHGR/L 25-5 5.00 6.40 50.0 25.0 25.0 140.00 41.0 22.9 4.20 - SR M6X16 DIN912 HW 5.0

GHGR/L 32-5 5.00 6.40 50.0 32.0 32.0 150.00 41.0 29.9 4.20 - SR M6X16 DIN912 HW 5.0

GHGR/L 25-630 6.00 8.00 60.0 25.0 25.0 140.00 45.0 22.3 5.40 - SR M6X16 DIN912 HW 5.0

GHGR/L 32-632 6.00 8.00 64.0 32.0 32.0 170.00 50.0 29.4 5.40 - SR M6X16 DIN912 HW 5.0

• For machining depth over 13 mm, a single-ended insert is required (GIM, GIMF, GIMY) • Tmax for grooving depth depends on part diameter D • For grooving a

part with a diameter larger than Dmax, see next table • For using TIP inserts, toolholder seat needs to be modified according to insert profile to ensure clearance •

For user guide, see pages 340-351

(1) In the case of inserts with W<2 mm, tool pocket should be ground to 0.3 mm thinner than the insert's grooving width.

(2) For Star and multi-spindle machines.

(3) Maximum parting diameter

For inserts, see pages: GIA-K (W=3-6) (254) • GIF (253) • GIF (full radius) (254) • GIF-E (W=4-6 full radius) (250) • GIF-E (W=4-6) (248) • GIG (252) • GIM-C (402)

• GIM-J (403) • GIM-J-RA/LA (403) • GIM-UT (404) • GIM-UT-RA/LA (404) • GIM-W (403) • GIM-W-RA/LA (404) • GIMF (244) • GIMM 8CC (454) • GIMN (245)

• GIMY (245) • GIMY (full radius) (246) • GIMY-F (247) • GIP (252) • GIP (flat top W

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017