Каталог Iscar токарный инструмент 2017 - страница 237

Навигация

l1

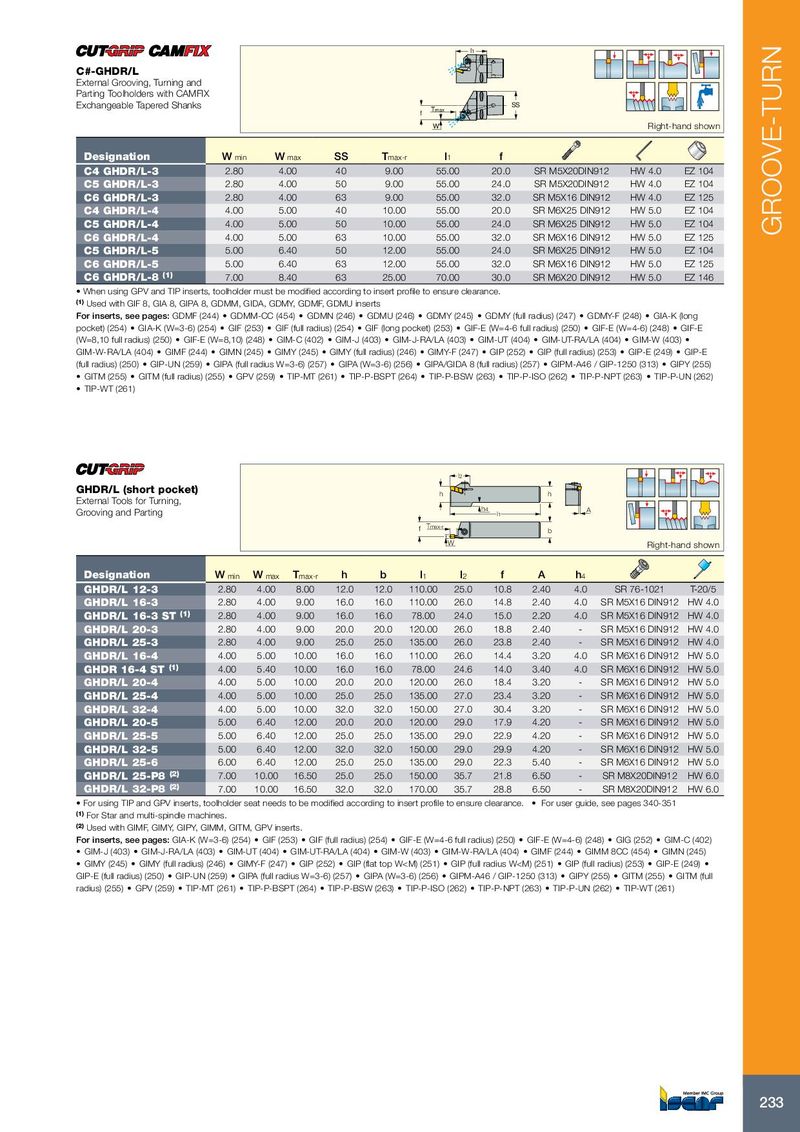

C#-GHDR/L

External Grooving, Turning and

Parting Toolholders with CAMFIX

Exchangeable Tapered Shanks SS

f T max

W Right-hand shown

Designation W min W max SS T max-r l 1 f

C4 GHDR/L-3 2.80 4.00 40 9.00 55.00 20.0 SR M5X20DIN912 HW 4.0 EZ 104

C5 GHDR/L-3 2.80 4.00 50 9.00 55.00 24.0 SR M5X20DIN912 HW 4.0 EZ 104

C6 GHDR/L-3 2.80 4.00 63 9.00 55.00 32.0 SR M5X16 DIN912 HW 4.0 EZ 125

C4 GHDR/L-4 4.00 5.00 40 10.00 55.00 20.0 SR M6X25 DIN912 HW 5.0 EZ 104

C5 GHDR/L-4 4.00 5.00 50 10.00 55.00 24.0 SR M6X25 DIN912 HW 5.0 EZ 104

GROOVE-TURN

C6 GHDR/L-4 4.00 5.00 63 10.00 55.00 32.0 SR M6X16 DIN912 HW 5.0 EZ 125

C5 GHDR/L-5 5.00 6.40 50 12.00 55.00 24.0 SR M6X25 DIN912 HW 5.0 EZ 104

C6 GHDR/L-5 5.00 6.40 63 12.00 55.00 32.0 SR M6X16 DIN912 HW 5.0 EZ 125

C6 GHDR/L-8 (1) 7.00 8.40 63 25.00 70.00 30.0 SR M6X20 DIN912 HW 5.0 EZ 146

• When using GPV and TIP inserts, toolholder must be modified according to insert profile to ensure clearance.

(1) Used with GIF 8, GIA 8, GIPA 8, GDMM, GIDA, GDMY, GDMF, GDMU inserts

For inserts, see pages: GDMF (244) • GDMM-CC (454) • GDMN (246) • GDMU (246) • GDMY (245) • GDMY (full radius) (247) • GDMY-F (248) • GIA-K (long

pocket) (254) • GIA-K (W=3-6) (254) • GIF (253) • GIF (full radius) (254) • GIF (long pocket) (253) • GIF-E (W=4-6 full radius) (250) • GIF-E (W=4-6) (248) • GIF-E

(W=8,10 full radius) (250) • GIF-E (W=8,10) (248) • GIM-C (402) • GIM-J (403) • GIM-J-RA/LA (403) • GIM-UT (404) • GIM-UT-RA/LA (404) • GIM-W (403) •

GIM-W-RA/LA (404) • GIMF (244) • GIMN (245) • GIMY (245) • GIMY (full radius) (246) • GIMY-F (247) • GIP (252) • GIP (full radius) (253) • GIP-E (249) • GIP-E

(full radius) (250) • GIP-UN (259) • GIPA (full radius W=3-6) (257) • GIPA (W=3-6) (256) • GIPA/GIDA 8 (full radius) (257) • GIPM-A46 / GIP-1250 (313) • GIPY (255)

• GITM (255) • GITM (full radius) (255) • GPV (259) • TIP-MT (261) • TIP-P-BSPT (264) • TIP-P-BSW (263) • TIP-P-ISO (262) • TIP-P-NPT (263) • TIP-P-UN (262)

• TIP-WT (261)

l2

GHDR/L (short pocket) h h

External Tools for Turning,

Grooving and Parting h 4

l1 A

f Tmax-r

b

W Right-hand shown

Designation W min W max T max-r h b l 1 l 2 f A h 4

GHDR/L 12-3 2.80 4.00 8.00 12.0 12.0 110.00 25.0 10.8 2.40 4.0 SR 76-1021 T-20/5

GHDR/L 16-3 2.80 4.00 9.00 16.0 16.0 110.00 26.0 14.8 2.40 4.0 SR M5X16 DIN912 HW 4.0

GHDR/L 16-3 ST (1) 2.80 4.00 9.00 16.0 16.0 78.00 24.0 15.0 2.20 4.0 SR M5X16 DIN912 HW 4.0

GHDR/L 20-3 2.80 4.00 9.00 20.0 20.0 120.00 26.0 18.8 2.40 - SR M5X16 DIN912 HW 4.0

GHDR/L 25-3 2.80 4.00 9.00 25.0 25.0 135.00 26.0 23.8 2.40 - SR M5X16 DIN912 HW 4.0

GHDR/L 16-4 4.00 5.00 10.00 16.0 16.0 110.00 26.0 14.4 3.20 4.0 SR M6X16 DIN912 HW 5.0

GHDR 16-4 ST (1) 4.00 5.40 10.00 16.0 16.0 78.00 24.6 14.0 3.40 4.0 SR M6X16 DIN912 HW 5.0

GHDR/L 20-4 4.00 5.00 10.00 20.0 20.0 120.00 26.0 18.4 3.20 - SR M6X16 DIN912 HW 5.0

GHDR/L 25-4 4.00 5.00 10.00 25.0 25.0 135.00 27.0 23.4 3.20 - SR M6X16 DIN912 HW 5.0

GHDR/L 32-4 4.00 5.00 10.00 32.0 32.0 150.00 27.0 30.4 3.20 - SR M6X16 DIN912 HW 5.0

GHDR/L 20-5 5.00 6.40 12.00 20.0 20.0 120.00 29.0 17.9 4.20 - SR M6X16 DIN912 HW 5.0

GHDR/L 25-5 5.00 6.40 12.00 25.0 25.0 135.00 29.0 22.9 4.20 - SR M6X16 DIN912 HW 5.0

GHDR/L 32-5 5.00 6.40 12.00 32.0 32.0 150.00 29.0 29.9 4.20 - SR M6X16 DIN912 HW 5.0

GHDR/L 25-6 6.00 6.40 12.00 25.0 25.0 135.00 29.0 22.3 5.40 - SR M6X16 DIN912 HW 5.0

GHDR/L 25-P8 (2) 7.00 10.00 16.50 25.0 25.0 150.00 35.7 21.8 6.50 - SR M8X20DIN912 HW 6.0

GHDR/L 32-P8 (2) 7.00 10.00 16.50 32.0 32.0 170.00 35.7 28.8 6.50 - SR M8X20DIN912 HW 6.0

• For using TIP and GPV inserts, toolholder seat needs to be modified according to insert profile to ensure clearance. • For user guide, see pages 340-351

(1) For Star and multi-spindle machines.

(2) Used with GIMF, GIMY, GIPY, GIMM, GITM, GPV inserts.

For inserts, see pages: GIA-K (W=3-6) (254) • GIF (253) • GIF (full radius) (254) • GIF-E (W=4-6 full radius) (250) • GIF-E (W=4-6) (248) • GIG (252) • GIM-C (402)

• GIM-J (403) • GIM-J-RA/LA (403) • GIM-UT (404) • GIM-UT-RA/LA (404) • GIM-W (403) • GIM-W-RA/LA (404) • GIMF (244) • GIMM 8CC (454) • GIMN (245)

• GIMY (245) • GIMY (full radius) (246) • GIMY-F (247) • GIP (252) • GIP (flat top W

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017