Каталог Iscar токарный инструмент 2017 - страница 234

Навигация

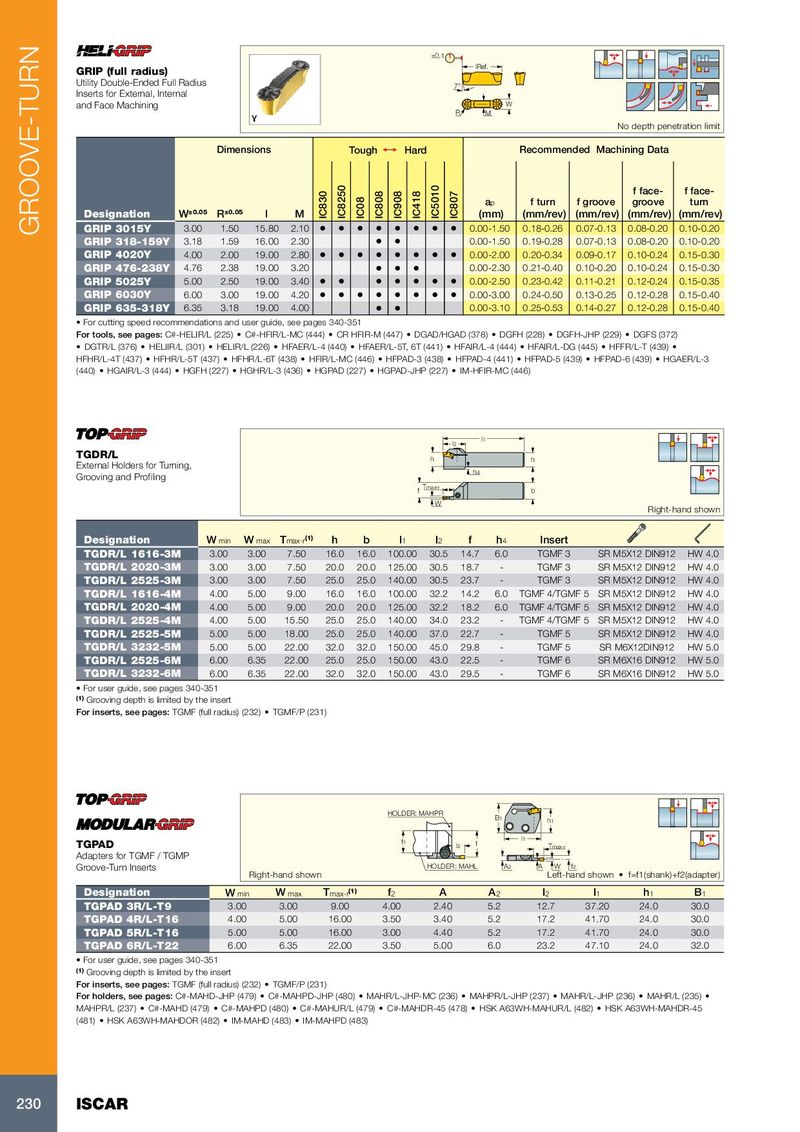

±0.1 lRef. GRIP (full radius) Utility Double-Ended Full Radius 7° Inserts for External, Internal and Face Machining W R M No depth penetration limit Dimensions Tough 1 Hard Recommended Machining Data f face- f face- a p f turn f groove groove turn Designation W ±0.05 R ±0.05 l M IC830 IC8250 IC08 IC808 IC908 IC418 IC5010 IC807 (mm) (mm/rev) (mm/rev) (mm/rev) (mm/rev) GROOVE-TURN GRIP 3015Y 3.00 1.50 15.80 2.10 • • • • • • • • 0.00-1.50 0.18-0.26 0.07-0.13 0.08-0.20 0.10-0.20 GRIP 318-159Y 3.18 1.59 16.00 2.30 • • 0.00-1.50 0.19-0.28 0.07-0.13 0.08-0.20 0.10-0.20 GRIP 4020Y 4.00 2.00 19.00 2.80 • • • • • • • • 0.00-2.00 0.20-0.34 0.09-0.17 0.10-0.24 0.15-0.30 GRIP 476-238Y 4.76 2.38 19.00 3.20 • • • 0.00-2.30 0.21-0.40 0.10-0.20 0.10-0.24 0.15-0.30 GRIP 5025Y 5.00 2.50 19.00 3.40 • • • • • • • 0.00-2.50 0.23-0.42 0.11-0.21 0.12-0.24 0.15-0.35 GRIP 6030Y 6.00 3.00 19.00 4.20 • • • • • • • • 0.00-3.00 0.24-0.50 0.13-0.25 0.12-0.28 0.15-0.40 GRIP 635-318Y 6.35 3.18 19.00 4.00 • • 0.00-3.10 0.25-0.53 0.14-0.27 0.12-0.28 0.15-0.40 • For cutting speed recommendations and user guide, see pages 340-351 For tools, see pages: C#-HELIR/L (225) • C#-HFIR/L-MC (444) • CR HFIR-M (447) • DGAD/HGAD (378) • DGFH (228) • DGFH-JHP (229) • DGFS (372) • DGTR/L (376) • HELIIR/L (301) • HELIR/L (226) • HFAER/L-4 (440) • HFAER/L-5T, 6T (441) • HFAIR/L-4 (444) • HFAIR/L-DG (445) • HFFR/L-T (439) • HFHR/L-4T (437) • HFHR/L-5T (437) • HFHR/L-6T (438) • HFIR/L-MC (446) • HFPAD-3 (438) • HFPAD-4 (441) • HFPAD-5 (439) • HFPAD-6 (439) • HGAER/L-3 (440) • HGAIR/L-3 (444) • HGFH (227) • HGHR/L-3 (436) • HGPAD (227) • HGPAD-JHP (227) • IM-HFIR-MC (446) l1 l2 TGDR/L h h External Holders for Turning, h4 Grooving and Profiling f Tmax-r b W Right-hand shown Designation W min W max T max-r (1) h b l 1 l 2 f h 4 Insert TGDR/L 1616-3M 3.00 3.00 7.50 16.0 16.0 100.00 30.5 14.7 6.0 TGMF 3 SR M5X12 DIN912 HW 4.0 TGDR/L 2020-3M 3.00 3.00 7.50 20.0 20.0 125.00 30.5 18.7 - TGMF 3 SR M5X12 DIN912 HW 4.0 TGDR/L 2525-3M 3.00 3.00 7.50 25.0 25.0 140.00 30.5 23.7 - TGMF 3 SR M5X12 DIN912 HW 4.0 TGDR/L 1616-4M 4.00 5.00 9.00 16.0 16.0 100.00 32.2 14.2 6.0 TGMF 4/TGMF 5 SR M5X12 DIN912 HW 4.0 TGDR/L 2020-4M 4.00 5.00 9.00 20.0 20.0 125.00 32.2 18.2 6.0 TGMF 4/TGMF 5 SR M5X12 DIN912 HW 4.0 TGDR/L 2525-4M 4.00 5.00 15.50 25.0 25.0 140.00 34.0 23.2 - TGMF 4/TGMF 5 SR M5X12 DIN912 HW 4.0 TGDR/L 2525-5M 5.00 5.00 18.00 25.0 25.0 140.00 37.0 22.7 - TGMF 5 SR M5X12 DIN912 HW 4.0 TGDR/L 3232-5M 5.00 5.00 22.00 32.0 32.0 150.00 45.0 29.8 - TGMF 5 SR M6X12DIN912 HW 5.0 TGDR/L 2525-6M 6.00 6.35 22.00 25.0 25.0 150.00 43.0 22.5 - TGMF 6 SR M6X16 DIN912 HW 5.0 TGDR/L 3232-6M 6.00 6.35 22.00 32.0 32.0 150.00 43.0 29.5 - TGMF 6 SR M6X16 DIN912 HW 5.0 • For user guide, see pages 340-351 (1) Grooving depth is limited by the insert For inserts, see pages: TGMF (full radius) (232) • TGMF/P (231) HOLDER: MAHPR B1 h1 TGPAD f1 l1 l2 f Tmax-r Adapters for TGMF / TGMP Groove-Turn Inserts HOLDER: MAHL A2 A W f2 Right-hand shown Left-hand shown • f=f1(shank)+f2(adapter) Designation W min W max T max-r (1) f 2 A A 2 l 2 l 1 h 1 B 1 TGPAD 3R/L-T9 3.00 3.00 9.00 4.00 2.40 5.2 12.7 37.20 24.0 30.0 TGPAD 4R/L-T16 4.00 5.00 16.00 3.50 3.40 5.2 17.2 41.70 24.0 30.0 TGPAD 5R/L-T16 5.00 5.00 16.00 3.00 4.40 5.2 17.2 41.70 24.0 30.0 TGPAD 6R/L-T22 6.00 6.35 22.00 3.50 5.00 6.0 23.2 47.10 24.0 32.0 • For user guide, see pages 340-351 (1) Grooving depth is limited by the insert For inserts, see pages: TGMF (full radius) (232) • TGMF/P (231) For holders, see pages: C#-MAHD-JHP (479) • C#-MAHPD-JHP (480) • MAHR/L-JHP-MC (236) • MAHPR/L-JHP (237) • MAHR/L-JHP (236) • MAHR/L (235) • MAHPR/L (237) • C#-MAHD (479) • C#-MAHPD (480) • C#-MAHUR/L (479) • C#-MAHDR-45 (478) • HSK A63WH-MAHUR/L (482) • HSK A63WH-MAHDR-45 (481) • HSK A63WH-MAHDOR (482) • IM-MAHD (483) • IM-MAHPD (483) 230 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017