Каталог Iscar токарный инструмент 2017 - страница 201

Навигация

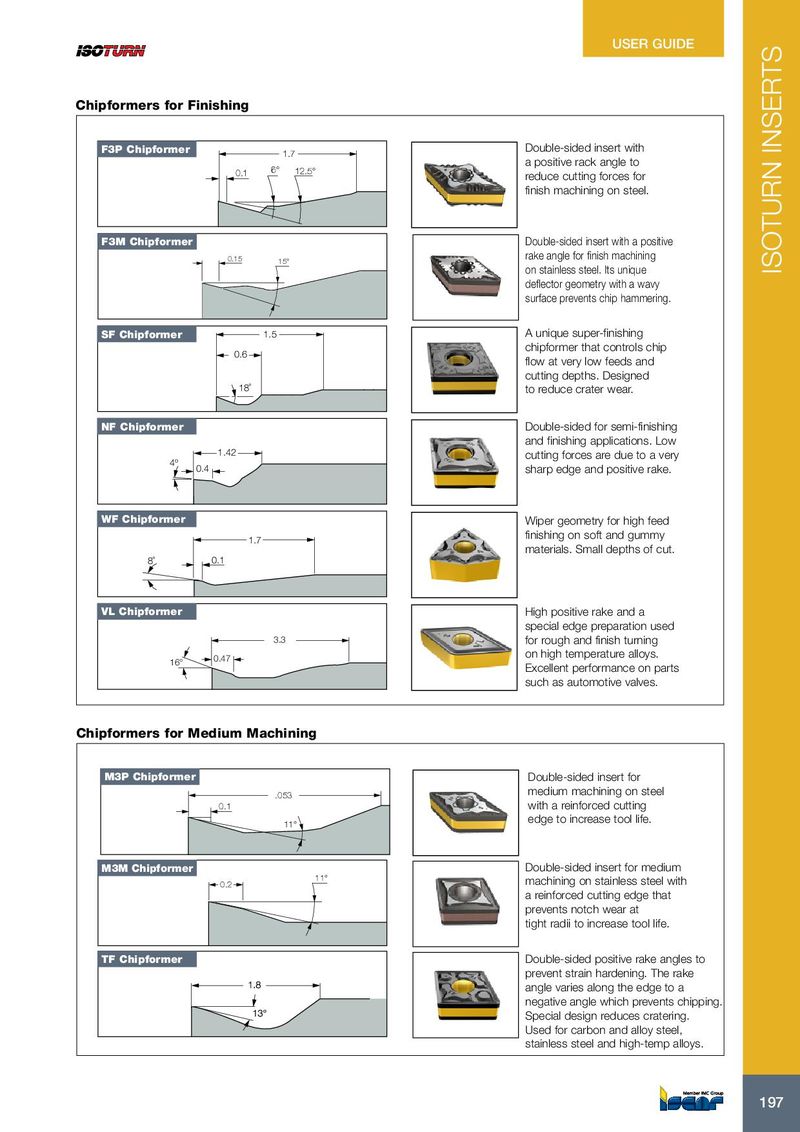

USER GUIDE Chipformers for Finishing F3P Chipformer Double-sided insert with 1.7 a positive rack angle to 0.1 6° 12.5° reduce cutting forces for finish machining on steel. F3M Chipformer Double-sided insert with a positive 0.15 rake angle for finish machining 15° on stainless steel. Its unique ISOTURN INSERTS deflector geometry with a wavy surface prevents chip hammering. SF Chipformer 1.5 A unique super-finishing chipformer that controls chip 0.6 flow at very low feeds and cutting depths. Designed 18˚ to reduce crater wear. NF Chipformer Double-sided for semi-finishing and finishing applications. Low 1.42 cutting forces are due to a very 4º 0.4 sharp edge and positive rake. WF Chipformer Wiper geometry for high feed finishing on soft and gummy 1.7 materials. Small depths of cut. 8˚ 0.1 VL Chipformer High positive rake and a special edge preparation used 3.3 for rough and finish turning on high temperature alloys. 16° 0.47 Excellent performance on parts such as automotive valves. Chipformers for Medium Machining M3P Chipformer Double-sided insert for .053 medium machining on steel 0.1 with a reinforced cutting edge to increase tool life. 11° M3M Chipformer Double-sided insert for medium 11° 0.2 machining on stainless steel with a reinforced cutting edge that prevents notch wear at tight radii to increase tool life. TF Chipformer Double-sided positive rake angles to prevent strain hardening. The rake angle varies along the edge to a negative angle which prevents chipping. Special design reduces cratering. Used for carbon and alloy steel, stainless steel and high-temp alloys. 197 197

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017