Каталог Iscar токарный инструмент 2017 - страница 158

Навигация

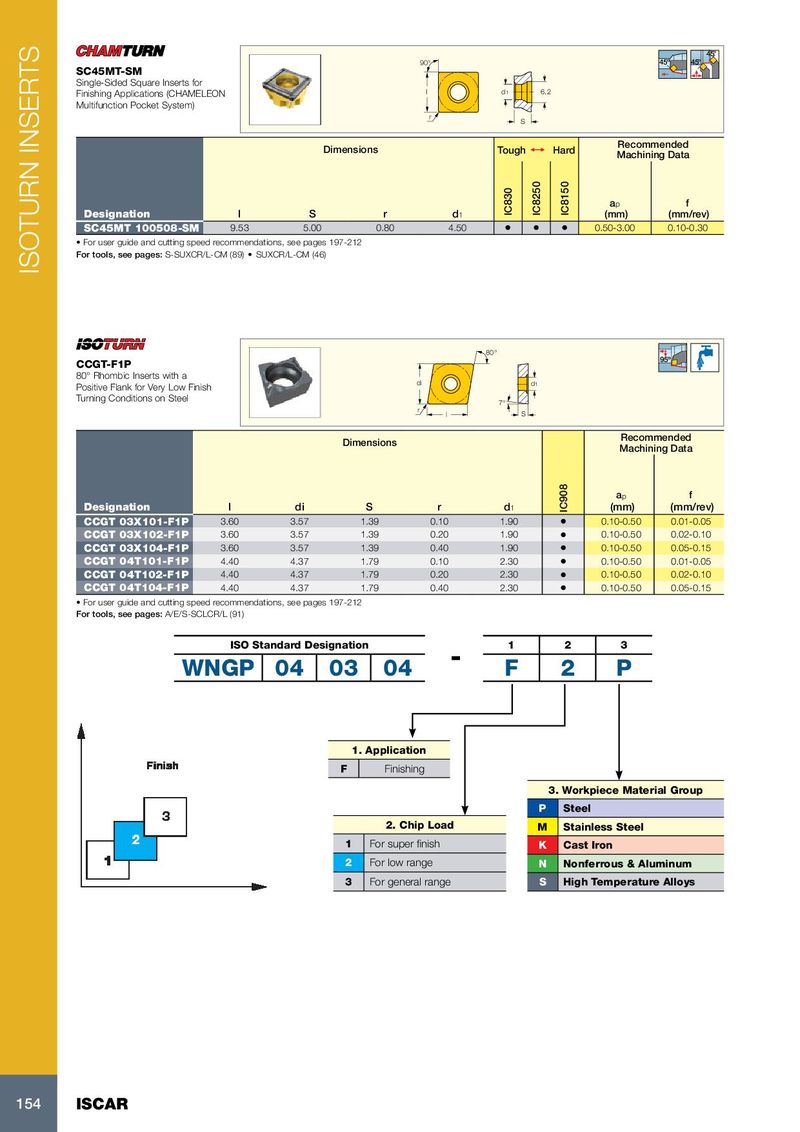

45° 90° 45º 45° SC45MT-SM Single-Sided Square Inserts for Finishing Applications (CHAMELEON I d 1 6.2 Multifunction Pocket System) r S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l S r d 1 IC830 IC8250 IC8150 (mm) (mm/rev) SC45MT 100508-SM 9.53 5.00 0.80 4.50 • • • 0.50-3.00 0.10-0.30 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: S-SUXCR/L-CM (89) • SUXCR/L-CM (46) ISOTURN INSERTS 80° 95º CCGT-F1P 80° Rhombic Inserts with a di d 1 Positive Flank for Very Low Finish Turning Conditions on Steel 7° r l S Recommended Dimensions Machining Data a p f Designation l di S r d 1 IC908 (mm) (mm/rev) CCGT 03X101-F1P 3.60 3.57 1.39 0.10 1.90 • 0.10-0.50 0.01-0.05 CCGT 03X102-F1P 3.60 3.57 1.39 0.20 1.90 • 0.10-0.50 0.02-0.10 CCGT 03X104-F1P 3.60 3.57 1.39 0.40 1.90 • 0.10-0.50 0.05-0.15 CCGT 04T101-F1P 4.40 4.37 1.79 0.10 2.30 • 0.10-0.50 0.01-0.05 CCGT 04T102-F1P 4.40 4.37 1.79 0.20 2.30 • 0.10-0.50 0.02-0.10 CCGT 04T104-F1P 4.40 4.37 1.79 0.40 2.30 • 0.10-0.50 0.05-0.15 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/E/S-SCLCR/L (91) ISO Standard Designation 1 2 3 - WNGP 04 03 04 F 2 P 1. Application F Finishing 3. Workpiece Material Group P Steel 2. Chip Load M Stainless Steel 1 For super finish K Cast Iron 2 For low range N Nonferrous & Aluminum 3 For general range S High Temperature Alloys 154 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017