Каталог Iscar токарный инструмент 2017 - страница 159

Навигация

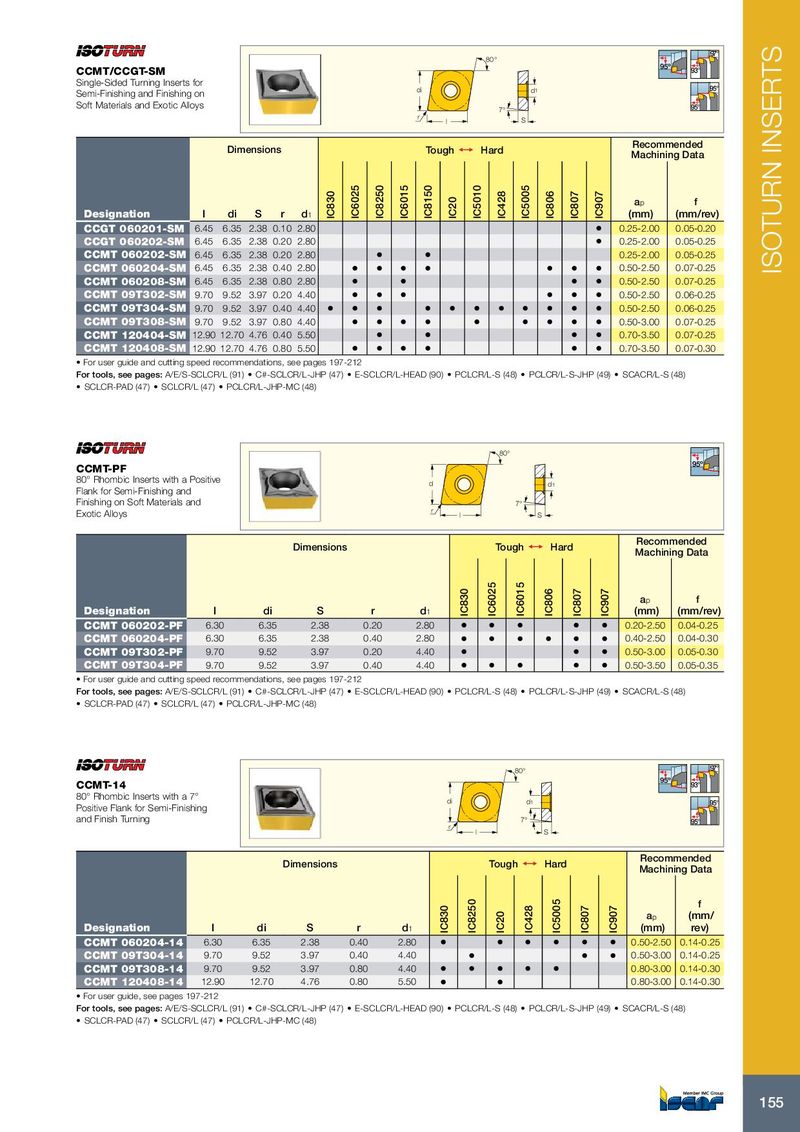

97° 80° 95º CCMT/CCGT-SM 93° Single-Sided Turning Inserts for di d 1 95° Semi-Finishing and Finishing on Soft Materials and Exotic Alloys 7° 95° r l S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r d 1 IC830 IC6025 IC8250 IC6015 IC8150 IC20 IC5010 IC428 IC5005 IC806 IC807 IC907 (mm) (mm/rev) CCGT 060201-SM 6.45 6.35 2.38 0.10 2.80 • 0.25-2.00 0.05-0.20 CCGT 060202-SM 6.45 6.35 2.38 0.20 2.80 • 0.25-2.00 0.05-0.25 CCMT 060202-SM 6.45 6.35 2.38 0.20 2.80 • • 0.25-2.00 0.05-0.25 CCMT 060204-SM 6.45 6.35 2.38 0.40 2.80 • • • • • • • 0.50-2.50 0.07-0.25 ISOTURN INSERTS CCMT 060208-SM 6.45 6.35 2.38 0.80 2.80 • • • • 0.50-2.50 0.07-0.25 CCMT 09T302-SM 9.70 9.52 3.97 0.20 4.40 • • • • • • 0.50-2.50 0.06-0.25 CCMT 09T304-SM 9.70 9.52 3.97 0.40 4.40 • • • • • • • • • • • 0.50-2.50 0.06-0.25 CCMT 09T308-SM 9.70 9.52 3.97 0.80 4.40 • • • • • • • • • 0.50-3.00 0.07-0.25 CCMT 120404-SM 12.90 12.70 4.76 0.40 5.50 • • • • 0.70-3.50 0.07-0.25 CCMT 120408-SM 12.90 12.70 4.76 0.80 5.50 • • • • • • 0.70-3.50 0.07-0.30 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/E/S-SCLCR/L (91) • C#-SCLCR/L-JHP (47) • E-SCLCR/L-HEAD (90) • PCLCR/L-S (48) • PCLCR/L-S-JHP (49) • SCACR/L-S (48) • SCLCR-PAD (47) • SCLCR/L (47) • PCLCR/L-JHP-MC (48) 80° 95º CCMT-PF 80° Rhombic Inserts with a Positive d d 1 Flank for Semi-Finishing and Finishing on Soft Materials and 7° Exotic Alloys r l S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r d 1 IC830 IC6025 IC6015 IC806 IC807 IC907 (mm) (mm/rev) CCMT 060202-PF 6.30 6.35 2.38 0.20 2.80 • • • • • 0.20-2.50 0.04-0.25 CCMT 060204-PF 6.30 6.35 2.38 0.40 2.80 • • • • • • 0.40-2.50 0.04-0.30 CCMT 09T302-PF 9.70 9.52 3.97 0.20 4.40 • • • 0.50-3.00 0.05-0.30 CCMT 09T304-PF 9.70 9.52 3.97 0.40 4.40 • • • • • 0.50-3.50 0.05-0.35 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/E/S-SCLCR/L (91) • C#-SCLCR/L-JHP (47) • E-SCLCR/L-HEAD (90) • PCLCR/L-S (48) • PCLCR/L-S-JHP (49) • SCACR/L-S (48) • SCLCR-PAD (47) • SCLCR/L (47) • PCLCR/L-JHP-MC (48) 80° 97° 95º CCMT-14 93° 80° Rhombic Inserts with a 7° di d 1 95° Positive Flank for Semi-Finishing and Finish Turning 7° 95° r l S Recommended Dimensions Tough 1 Hard Machining Data f a p (mm/ Designation l di S r d 1 IC830 IC8250 IC20 IC428 IC5005 IC807 IC907 (mm) rev) CCMT 060204-14 6.30 6.35 2.38 0.40 2.80 • • • • • • 0.50-2.50 0.14-0.25 CCMT 09T304-14 9.70 9.52 3.97 0.40 4.40 • • • 0.50-3.00 0.14-0.25 CCMT 09T308-14 9.70 9.52 3.97 0.80 4.40 • • • • • 0.80-3.00 0.14-0.30 CCMT 120408-14 12.90 12.70 4.76 0.80 5.50 • • 0.80-3.00 0.14-0.30 • For user guide, see pages 197-212 For tools, see pages: A/E/S-SCLCR/L (91) • C#-SCLCR/L-JHP (47) • E-SCLCR/L-HEAD (90) • PCLCR/L-S (48) • PCLCR/L-S-JHP (49) • SCACR/L-S (48) • SCLCR-PAD (47) • SCLCR/L (47) • PCLCR/L-JHP-MC (48) 155

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017