Каталог Iscar токарный инструмент 2017 - страница 152

Навигация

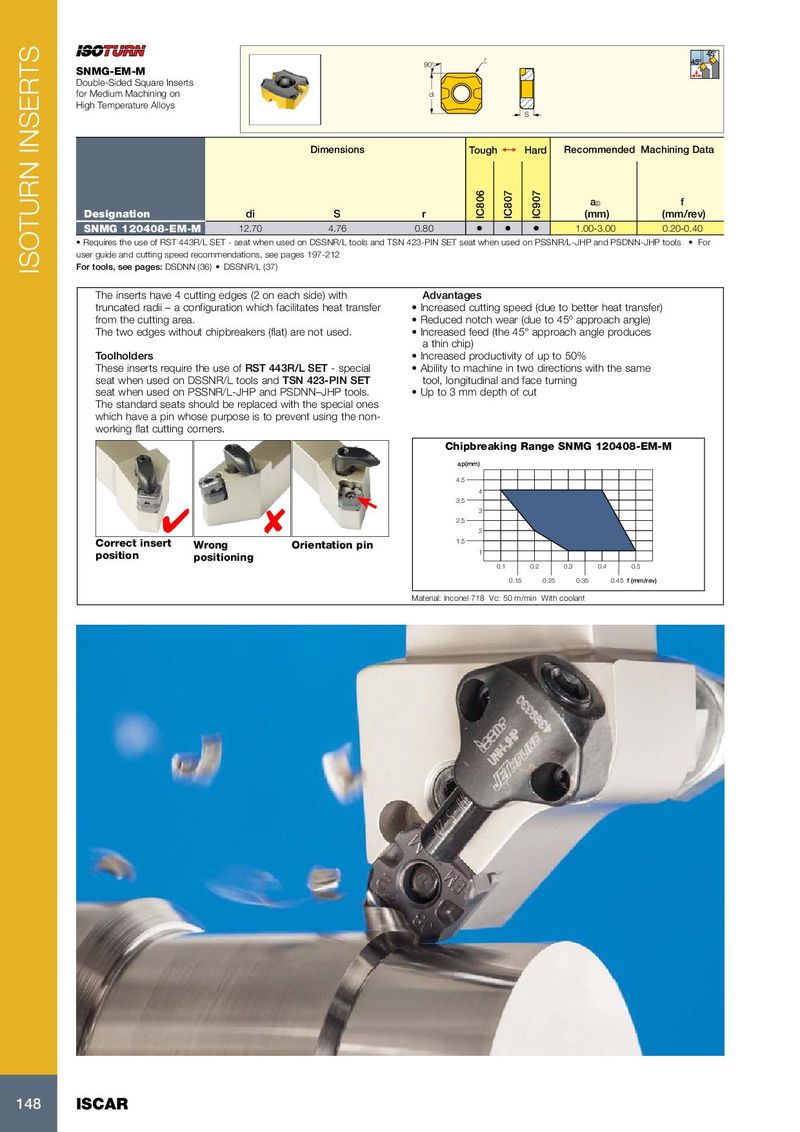

45° r 90° 45° SNMG-EM-M Double-Sided Square Inserts for Medium Machining on di High Temperature Alloys S Dimensions Tough 1 Hard Recommended Machining Data a p f Designation di S r IC806 IC807 IC907 (mm) (mm/rev) SNMG 120408-EM-M 12.70 4.76 0.80 • • • 1.00-3.00 0.20-0.40 • Requires the use of RST 443R/L SET - seat when used on DSSNR/L tools and TSN 423-PIN SET seat when used on PSSNR/L-JHP and PSDNN-JHP tools • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: DSDNN (36) • DSSNR/L (37) ISOTURN INSERTS The inserts have 4 cutting edges (2 on each side) with Advantages truncated radii – a configuration which facilitates heat transfer • Increased cutting speed (due to better heat transfer) from the cutting area. • Reduced notch wear (due to 45º approach angle) The two edges without chipbreakers (flat) are not used. • Increased feed (the 45° approach angle produces a thin chip) Toolholders • Increased productivity of up to 50% These inserts require the use of RST 443R/L SET - special • Ability to machine in two directions with the same seat when used on DSSNR/L tools and TSN 423-PIN SET tool, longitudinal and face turning seat when used on PSSNR/L-JHP and PSDNN–JHP tools. • Up to 3 mm depth of cut The standard seats should be replaced with the special ones which have a pin whose purpose is to prevent using the non- working flat cutting corners. Chipbreaking Range SNMG 120408-EM-M ap(mm) 4.5 4 3.5 3 2.5 2 Correct insert 1.5 Wrong Orientation pin 1 position positioning 0.1 0.2 0.3 0.4 0.5 0.15 0.25 0.35 0.45 f (mm/rev) Material: Inconel 718 Vc: 50 m/min With coolant 148 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017