Каталог Iscar торцевые фрезы 2022 - страница 85

Навигация

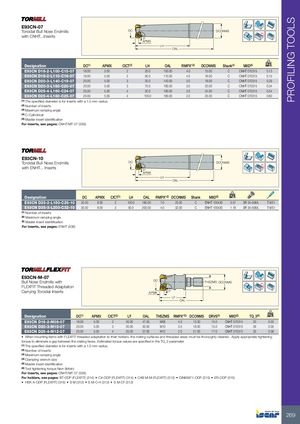

PROFILING TOOLS E93CN-07 Toroidal Bull Nose Endmills DC DCONMS Rd° with CNHT...Inserts 3° APMX LH OAL Designation DC(1) APMX CICT(2) LH OAL RMPX°(3) DCONMS Shank(4) MIID(5) kg E93CN D16-2-L100-C15-07 16.00 5.00 2 20.0 100.00 4.0 15.00 C CNHT 070315 0.13 E93CN D16-2-L110-C16-07 16.00 5.00 2 50.0 110.00 4.0 16.00 C CNHT 070315 0.15 E93CN D20-3-L140-C19-07 20.00 5.00 3 20.0 140.00 3.0 19.00 C CNHT 070315 0.29 E93CN D20-3-L160-C20-07 20.00 5.00 3 75.0 160.00 3.0 20.00 C CNHT 070315 0.34 E93CN D25-4-L160-C24-07 25.00 5.00 4 20.0 160.00 2.0 24.00 C CNHT 070315 0.54 E93CN D25-4-L180-C25-07 25.00 5.00 4 100.0 180.00 2.0 25.00 C CNHT 070315 0.60 (1) The specified diameter is for inserts with a 1.0 mm radius. (2) Number of inserts (3) Maximum ramping angle (4) C-Cylindrical (5) Master insert identification For inserts, see pages: CNHT/MT 07 (538) E93CN-10 Toroidal Bull Nose Endmills DC DCONMS Rd° with ENHT... Inserts 3° APMX LH OAL Designation DC APMX CICT(1) LH OAL RMPX°(2) DCONMS Shank MIID(3) kg E93CN D25-2-L180-C25-10 25.00 8.00 2 100.0 180.00 7.0 25.00 C ENHT 100430 0.57 SR 34-506/L T-9/51 E93CN D35-3-L200-C32-10 35.00 8.00 3 50.0 200.00 4.0 32.00 C ENHT 100430 1.18 SR 34-506/L T-9/51 (1) Number of inserts (2) Maximum ramping angle (3) Master insert identification For inserts, see pages: ENHT (538) E93CN-M-07 Bull Nose Endmills with DC THSZMS DCONMS Rd° FLEXFIT Threaded Adaptation Carrying Toroidal Inserts APMX 3° LF OAL Designation DC(1) APMX CICT(2) LF OAL THSZMS RMPX°(3) DCONMS DRVS(4) MIID(5) TQ_3(6) kg E93CN D16-2-M08-07 16.00 5.00 2 30.00 47.50 M08 4.0 13.00 10.0 CNHT 070315 20 0.03 E93CN D20-3-M10-07 20.00 5.00 3 30.00 50.00 M10 3.0 18.00 15.0 CNHT 070315 29 0.05 E93CN D25-4-M12-07 25.00 5.00 4 35.00 57.00 M12 2.0 21.00 17.0 CNHT 070315 33 0.09 • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the TQ_3 parameter (1) The specified diameter is for inserts with a 1.0 mm radius. (2) Number of inserts (3) Maximum ramping angle (4) Clamping wrench size (5) Master insert identification (6) Tool tightening torque Nxm (lbfxin) For inserts, see pages: CNHT/MT 07 (538) For holders, see pages: BT-ODP (FLEXFIT) (314) • C#-ODP (FLEXFIT) (314) • CAB M-M (FLEXFIT) (312) • DIN69871-ODP (315) • ER-ODP (315) • HSK A-ODP (FLEXFIT) (316) • S M (312) • S M-C-H (312) • S M-CF (313) 269

Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022 Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar отрезка 2022

Каталог Iscar отрезка 2022 Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные сверла 2022

Каталог Iscar монолитные сверла 2022