Каталог Iscar сверла со сменной режущей частью 2022 - страница 77

Навигация

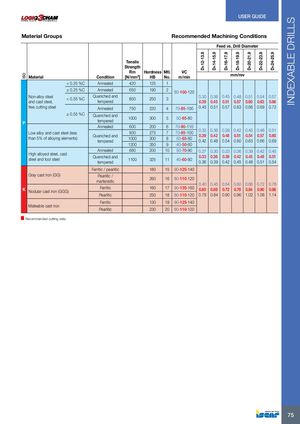

ISO D=12-13.9 D=14-15.9 D=16-17.9 D=18-19.9 D=20-21.9 D=22-23.9 D=24-25.9 INDEXABLE DRILLS USER GUIDE Material Groups Recommended Machining Conditions Feed vs. Drill Diameter Tensile Strength Rm Hardness Mtl. VC Material Condition [N/mm2] HB No. m/min mm/rev < 0.25 %C Annealed 420 125 1 ≥ 0.25 %C Annealed 650 190 2 80-100-120 Non-alloy steeland cast steel,< 0.55 %CQuenched andtempered 850 250 3 0.30 0.36 0.45 0.48 0.51 0.54 0.570.390.450.510.570.600.630.66 free cutting steel Annealed 750 220 4 70-85-100 0.45 0.51 0.57 0.63 0.66 0.69 0.72 P ≥ 0.55 %C Quenched andtempered 1000 300 5 50-65-80 Annealed 600 200 6 70-90-110 Low alloy and cast steel (lessthan 5% of alloying elements) 930Quenched andtempered10002753007870-85-10050-65-800.330.360.39 0.42 0.45 0.48 0.510.390.420.480.510.540.570.600.420.480.540.600.630.660.69 1200 350 9 40-50-60 High alloyed steel, caststeel and tool steelAnnealed 680 200 10 50-70-90 0.27 0.30 0.33 0.36 0.39 0.42 0.45Quenched andtempered11000.330.360.390.420.450.480.513251140-60-800.360.390.420.450.480.510.54 Ferritic / pearlitic 180 15 90-125-140 Gray cast iron (GG) Pearlitic /martensitic 260 16 80-110-120 0.40 0.45 0.54 0.60 0.66 0.72 0.78 K Nodular cast iron (GGG) Ferritic 160 17 90-135-160 0.60 0.66 0.72 0.78 0.84 0.90 0.96 Pearlitic 250 18 80-110-120 0.78 0.84 0.90 0.96 1.02 1.08 1.14 Ferritic 130 19 90-125-140 Malleable cast iron Pearlitic 230 20 80-110-120 Recommended cutting data 75

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar инструмент для мелкоразмерной обработки

Каталог Iscar инструмент для мелкоразмерной обработки Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022