Каталог Iscar обработка канавок 2022 - страница 80

Навигация

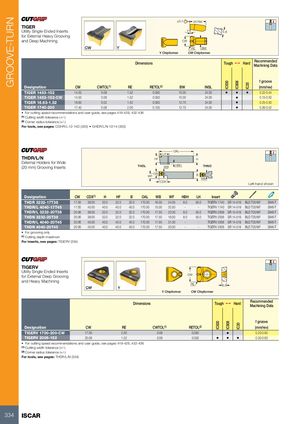

GROOVE-TURN IC830 IC830IC808 IC808IC20 IC20 ±0.1 24 Ref. TIGER Utility Single-Ended Inserts 7° 5.9 for External Heavy Grooving and Deep Machining CW RE BW Y Chipformer CW Chipformer Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW CWTOL(1) RE RETOL(2) BW INSL (mm/rev) TIGER 1453-152 14.53 0.08 1.52 0.050 10.00 24.00 • • • 0.22-0.44 TIGER 1453-152-CW 14.53 0.08 1.52 0.050 10.00 24.00 • 0.15-0.50 TIGER 16.63-1.52 16.63 0.02 1.52 0.050 12.70 24.00 • 0.25-0.50 TIGER 1740-200 17.40 0.08 2.00 0.100 12.70 24.00 • 0.26-0.52 • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: CGHR/L-12-14D (333) • GHDR/L/N 12/14 (333) OAL LH THDR/L/N HF H External Holders for Wide (20 mm) Grooving Inserts THDL WB HBH THND CWWF B WB CDX Left-hand shown Designation CW CDX(1) H HF B OAL WB WF HBH LH Insert THDR 3232-17T38 17.00 38.00 32.0 32.0 32.0 170.00 16.00 24.00 8.0 50.0 TIGERV 1740 SR 14-519 BLD T20/M7 SW6-T THDR/L 4040-17T45 17.00 45.00 40.0 40.0 40.0 170.00 15.00 32.50 - - TIGERV 1740 SR 14-519 BLD T20/M7 SW6-T THDR/L 3232-20T38 20.06 38.00 32.0 32.0 32.0 170.00 17.50 23.30 8.0 50.0 TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T THDN 3232-20T38 20.06 38.00 32.0 32.0 32.0 170.00 17.50 16.00 8.0 50.0 TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T THDR/L 4040-20T45 20.06 45.00 40.0 40.0 40.0 170.00 17.50 31.30 - - TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T THDN 4040-20T45 20.06 45.00 40.0 40.0 40.0 170.00 17.50 20.00 - - TIGERV 2006 SR 14-519 BLD T20/M7 SW6-T • For grooving only (1) Cutting depth maximum For inserts, see pages: TIGERV (334) TIGERV Utility Single-Ended Inserts for External Deep Grooving CW and Heavy Machining RE 6.5 Y Chipformer CW Chipformer Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) (mm/rev) TIGERV 1700-200-CW 17.00 2.00 0.08 0.050 • 0.20-0.60 TIGERV 2006-152 20.06 1.52 0.08 0.050 • • • 0.30-0.60 • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: THDR/L/N (334) 334 ISCAR

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022