Каталог Iscar обработка канавок 2022 - страница 202

Навигация

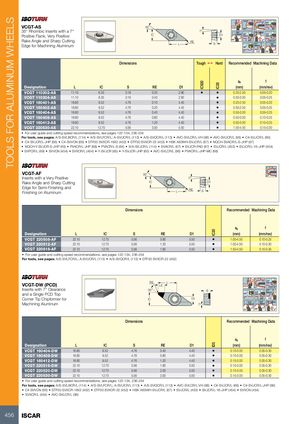

TOOLS FOR ALUMINUM WHEELS IC920 IC20ID5 IC20 142º 30° VCGT-AS MAX35˚117.5°93º93º 35° Rhombic Inserts with a 7°Positive Flank, Very Positive IC 7° D1 50°MAX 48° 70°MAX 35°MAXMAX Rake Angle and Sharp CuttingEdge for Machining Aluminum REL 93° 95º 72.5º 107.5ºS31°52°95ºMAXMAX 112° 91° Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE D1 (mm) (mm/rev) VCGT 110302-AS 11.10 6.35 3.18 0.20 2.90 • • 0.20-2.50 0.05-0.20 VCGT 110304-AS 11.10 6.35 3.18 0.40 2.90 • 0.50-3.00 0.05-0.25 VCGT 160401-AS 16.60 9.52 4.76 0.10 4.40 • 0.20-2.50 0.05-0.20 VCGT 160402-AS 16.60 9.52 4.76 0.20 4.40 • 0.50-2.50 0.05-0.25 VCGT 160404-AS 16.60 9.52 4.76 0.40 4.40 • 0.50-3.00 0.05-0.25 VCGT 160408-AS 16.60 9.52 4.76 0.80 4.40 • 0.50-3.00 0.10-0.25 VCGT 160412-AS 16.60 9.52 4.76 1.20 4.40 • 0.50-3.00 0.10-0.25 VCGT 220530-AS 22.10 12.70 5.56 3.00 5.50 • 1.50-4.50 0.15-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-254 For tools, see pages: A/S-SVLBCR/L (114) • A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • AVC-SVLCR/L-VH (98) • AVC-SVUCR/L (95) • C#-SVJCR/L (66) • C#-SVJCR/L-JHP (66) • C#-SVVCN (69) • DTF50 SVXCR-16X2 (452) • DTF50 SVXCR-22 (452) • HSK A63WH-SVJCR/L (67) • NQCH-SVACR/L-S-JHP (67) • NQCH-Y-SVJCR-S-JHP (65) • PVACR/L-JHP (68) • PVACR/L-S (64) • S/A-SVJCR/L (114) • SVACR/L (67) • SVJCR-PAD (67) • SVJCR/L (453) • SVJCR/L-16-JHP (454) • SVPCR/L (69) • SVVCN (454) • SVXCR/L (454) • Y-SVJCR (65) • Y-SVJCR-JHP (65) • AVC-SVLCR/L (96) • PVACR/L-JHP-MC (68) VCGT-AF 35˚ Inserts with a Very Positive 7° Rake Angle and Sharp Cutting IC D1 Edge for Semi-Finishing andFinishing on Aluminum L RE S Dimensions Recommended Machining Data ap f Designation L IC S RE D1 (mm) (mm/rev) VCGT 220508-AF 22.10 12.70 5.56 0.80 5.50 • 1.00-4.50 0.10-0.25 VCGT 220512-AF 22.10 12.70 5.56 1.20 5.50 • 1.00-4.50 0.10-0.30 VCGT 220516-AF 22.10 12.70 5.56 1.60 5.50 • 1.50-4.50 0.10-0.35 • For user guide and cutting speed recommendations, see pages 122-134, 236-254 For tools, see pages: A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • DTF50 SVXCR-22 (452) VCGT-DW (PCD) RE L 35°MAXLE117.5°107.5º Inserts with 7° Clearanceand a Single PCD Top 35° S 31°95º48°MAXMAX Corner Tip Chipformer for IC D1 95º 112° Machining Aluminum 52° 50° 70°MAX7°MAXMAX 91° 93° 72.5º Dimensions Recommended Machining Data ap f Designation L IC S RE D1 (mm) (mm/rev) VCGT 160404-DW 16.60 9.52 4.76 0.40 4.40 • 0.10-3.00 0.05-0.30 VCGT 160408-DW 16.60 9.52 4.76 0.80 4.40 • 0.10-3.00 0.05-0.30 VCGT 160412-DW 16.60 9.52 4.76 1.20 4.40 • 0.10-3.00 0.05-0.30 VCGT 220516-DW 22.10 12.70 5.56 1.60 5.50 • 0.10-3.00 0.05-0.30 VCGT 220520-DW 22.10 12.70 5.56 2.00 5.50 • 0.10-3.00 0.05-0.30 VCGT 220530-DW 22.10 12.70 5.56 3.00 5.50 • 0.10-3.00 0.05-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-254 For tools, see pages: A/S-SVLBCR/L (114) • A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • AVC-SVLCR/L-VH (98) • C#-SVJCR/L (66) • C#-SVJCR/L-JHP (66) • C#-SVVCN (69) • DTF50 SVXCR-16X2 (452) • DTF50 SVXCR-22 (452) • HSK A63WH-SVJCR/L (67) • SVJCR/L (453) • SVJCR/L-16-JHP (454) • SVVCN (454) • SVXCR/L (454) • AVC-SVLCR/L (96) 456 ISCAR

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022