Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 62

Навигация

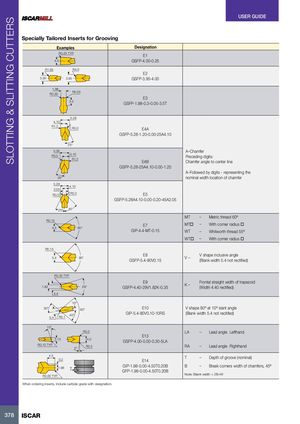

SLOTTING & SLITTING CUTTERS USER GUIDE Specially Tailored Inserts for Grooving Examples Designation R0.25 TYP. E1 4.0 GSFP-4.00-0.25 R1.65 R4.0 E2 3.30 3.95 GSFP-3.95-4.00 1.98 R0.30 R0.05 E3 3.5 GSFP-1.98-0.3-0.05-3.5T 5.28 4.10 R1.2 R0.0 E4A GSFP-5.28-1.20-0.00-25A4.10 25° 5.28 A–Chamfer R0.0 4.10 Preceding digits: R1.2 E4B Chamfer angle to center line GSFP-5.28-25A4.10-0.00-1.20 A–Followed by digits - representing the 25° nominal width location of chamfer 5.28 4.10 2.05 R0.0 R0.2 E5 GSFP-5.28A4.10-0.00-0.20-45A2.05 25° 45° MT – Metric thread 60º R0.15 E7 MT – With corner radius 4.4 60° GIP-4.4-MT-0.15 WT – Whitworth thread 55º WT – With corner radius R0.15 5.4 90° E8GSFP-5.4-90V0.15 V– V shape inclusive angle(Blank width 5.4 not rectified) R0.35 TYP. 1.82 29° E9GSFP-4.40-29V1.82K-0.35K– Frontal straight width of trapezoid(Width 4.40 rectified) 4.4 10° 50° 80° E10 V shape 80º at 10º slant angle 5.4 R0.1 40° GIP-5.4-80V0.10-10RS (Blank width 5.4 not recitifed) 15° R0.0 LA – Lead angle Lefthand E13 3.10 4.0 GSFP-4.00-0.00-0.30-5LA R0.10 TYP. 5° R0.3 RA – Lead angle Righthand 4.5 0.2 T – Depth of groove (nominal)E14 1.98 T GIP-1.98-0.00-4.50T0.20B B – Break corners width of chamfers, 45ºGFP-1.98-0.00-4.50T0.20B R0.00 TYP. Note: Blank width > 2B+W When ordering inserts, include carbide grade with designation. 378 ISCAR

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления