Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 59

Навигация

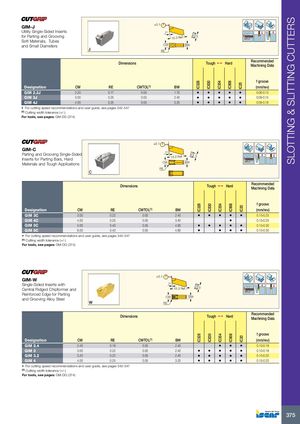

IC328IC328IC328 IC830IC830IC830 IC354IC354IC354 IC908IC908IC908 IC20IC20IC20 SLOTTING & SLITTING CUTTERS GIM-J ±0.1 Utility Single-Sided Inserts 7° for Parting and Grooving 15.3 Ref. 5 Soft Materials, Tubes and Small Diameters CW BW RE Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) BW (mm/rev) GIM 2.2J 2.20 0.17 0.05 1.70 • • • • • 0.06-0.13 GIM 3J 3.00 0.25 0.05 2.40 • • • • • 0.08-0.15 GIM 4J 4.00 0.25 0.05 3.20 • • • • • 0.08-0.18 • For cutting speed recommendations and user guide, see pages 542-547 (1) Cutting width tolerance (+/-) For tools, see pages: GM-DG (374) ±0.1 GIM-C Parting and Grooving Single-SidedInserts for Parting Bars, Hard 7° 15.3 Ref. 5 Materials and Tough Applications CW BW RE Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) BW (mm/rev) GIM 3C 3.00 0.22 0.05 2.40 • • • • • 0.15-0.25 GIM 4C 4.00 0.25 0.05 3.40 • 0.15-0.25 GIM 5C 5.00 0.40 0.05 4.00 • • • • • 0.15-0.30 GIM 6C 6.00 0.40 0.05 4.80 • • • • 0.15-0.30 • For cutting speed recommendations and user guide, see pages 542-547 (1) Cutting width tolerance (+/-) For tools, see pages: GM-DG (374) ±0.1 GIM-W Single-Sided Inserts with 7° Central Ridged Chipformer and 15.3 Ref. 5 Reinforced Edge for Parting and Grooving Alloy Steel CW BW RE Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) BW (mm/rev) GIM 2.4 2.40 0.18 0.05 2.40 • • • 0.10-0.18 GIM 3 3.00 0.22 0.05 2.40 • • • • • 0.10-0.18 GIM 3.2 3.20 0.22 0.05 2.40 • • • • • 0.10-0.20 GIM 4 4.00 0.25 0.05 3.20 • • • • • 0.15-0.20 • For cutting speed recommendations and user guide, see pages 542-547 (1) Cutting width tolerance (+/-) For tools, see pages: GM-DG (374) 375

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления