Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 216

Навигация

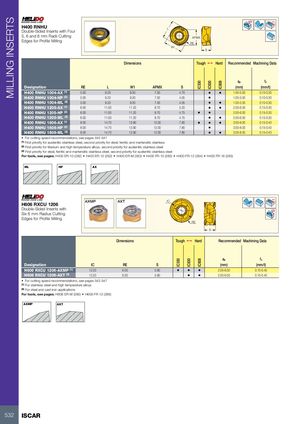

MILLING INSERTS IC330 IC830 IC330IC808 IC830 IC808 Rd° H400 RNHU L Double-Sided Inserts with Four 5, 6 and 8 mm Radii Cutting APMX Edges for Profile Milling RE W1 S Dimensions Tough 1 Hard Recommended Machining Data ap fz Designation RE L W1 APMX S (mm) (mm/t) H400 RNHU 1004-AX (1) 5.00 9.20 9.30 7.50 4.70 • • 1.00-5.00 0.10-0.30 H400 RNHU 1004-HP (2) 5.00 9.20 9.30 7.50 4.05 • 1.00-5.00 0.10-0.30 H400 RNHU 1004-ML (3) 5.00 9.20 9.30 7.50 4.05 • • 1.00-5.00 0.10-0.30 H400 RNHU 1205-AX (1) 6.00 11.00 11.20 8.70 5.20 • • 2.00-6.00 0.15-0.30 H400 RNHU 1205-HP (2) 6.00 11.00 11.20 8.70 4.75 • • 2.00-6.00 0.15-0.30 H400 RNHU 1205-ML (3) 6.00 11.00 11.20 8.70 4.75 • • 2.00-6.00 0.15-0.30 H400 RNHU 1606-AX (1) 8.00 14.70 13.90 12.00 7.80 • • • 3.00-8.00 0.15-0.40 H400 RNHU 1606-HP (2) 8.00 14.70 13.90 12.00 7.80 • 3.00-8.00 0.15-0.40 H400 RNHU 1606-ML (3) 8.00 14.70 13.90 12.00 7.80 • • 3.00-8.00 0.15-0.40 • For cutting speed recommendations, see pages 542-547 (1) First priority for austenitic stainless steel, second priority for steel, ferritic and martensitic stainless (2) First priority for titanium and high temperature alloys, second priority for austenitic stainless steel (3) First priority for steel, ferritic and martensitic stainless steel, second priority for austenitic stainless steel For tools, see pages: H400 ER-10 (282) • H400 ER-12 (282) • H400 ER-M (283) • H400 FR-10 (283) • H400 FR-12 (284) • H400 FR-16 (285) ML HP AX IC Rd° H606 RXCU 1206 Double-Sided Inserts with Six 6 mm Radius Cutting Edges for Profile Milling RE S Dimensions Tough 1 Hard Recommended Machining Data ap fz Designation IC RE S (mm) (mm/t) H606 RXCU 1206-AXMP (1) 12.20 6.00 5.90 • • • 2.00-6.00 0.10-0.40 H606 RXCU 1206-AXT (2) 12.20 6.00 5.90 • • 2.00-6.00 0.10-0.40 • For cutting speed recommendations, see pages 542-547 (1) For stainless steel and high temperature alloys (2) For steel and cast iron applications For tools, see pages: H606 ER-M (285) • H606 FR-12 (286) AXMP AXT 532 ISCAR

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления