Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 215

Навигация

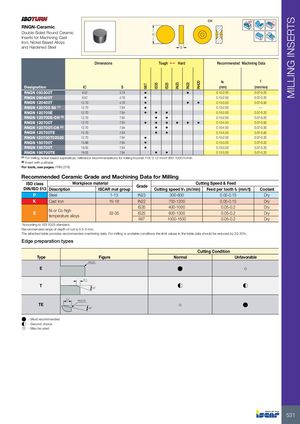

IW7 IS35 IS25 IN23 IN22 IN420 MILLING INSERTS CH Rd° RNGN-Ceramic Double-Sided Round Ceramic IC Inserts for Machining Cast Iron, Nickel Based Alloys and Hardened Steel S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation IC S (mm) (mm/rev) RNGN 090300T 9.52 3.18 • • 0.10-2.00 0.07-0.20 RNGN 090400T 9.52 4.76 • 0.10-2.00 0.07-0.20 RNGN 120400T 12.70 4.76 • • • 0.10-3.50 0.07-0.50 RNGN 120700 S6 (1) 12.70 7.94 • 0.10-2.00 --- RNGN 120700E 12.70 7.94 • • • 0.10-2.00 0.07-0.20 RNGN 120700E-CH (2) 12.70 7.94 • • 0.10-2.00 0.07-0.20 RNGN 120700T 12.70 7.94 • • • • • • 0.10-4.50 0.07-0.50 RNGN 120700T-CH (2) 12.70 7.94 • • 0.10-4.50 0.07-0.50 RNGN 120700TE 12.70 7.94 • • 0.10-4.50 0.07-0.50 RNGN 120700T02020 12.70 7.94 • 0.10-2.00 0.07-0.20 RNGN 150700T 15.88 7.94 • 0.10-3.00 0.07-0.20 RNGN 190700T 19.05 7.94 • 0.10-3.00 0.07-0.20 RNGN 190700TE 19.05 7.94 • • 0.10-3.00 0.07-0.20 (1) For milling nickel based superalloys; reference recommendations for milling Inconel 718: 0.12 mm/t 900-1000 m/min (2) Insert with a dimple For tools, see pages: FRN (278) Recommended Ceramic Grade and Machining Data for Milling ISO class Workpiece materialDIN/ISO 513DescriptionISCAR mat groupGrade Cutting Speed & FeedCutting speed Vc (m/min)Feed per tooth fz (mm/t)Coolant P Steel 1-13 IN23 300-600 0.05-0.15 Dry K Cast iron 15-18 IN22 700-1200 0.05-0.15 Dry IS35 400-1000 0.05-0.2 Dry S Ni or Co hightemperature alloys 33-35 IS25 600-1300 0.05-0.2 Dry IW7 1000-1500 0.05-0.2 Dry *According to VDI 3323 standard. Recommended range of depth of cut is 0.5-3 mm. The attached table provides recommended machining data. For milling is unstable conditions the limit values in the table data should be reduced by 20-30%. Edge preparation types Cutting Condition Type Figure Normal Unfavorable R0.03 E 0.1 T 20 0.1 R0.015 TE 20 - Most recommended - Second choice - May be used 531

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления