Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 187

Навигация

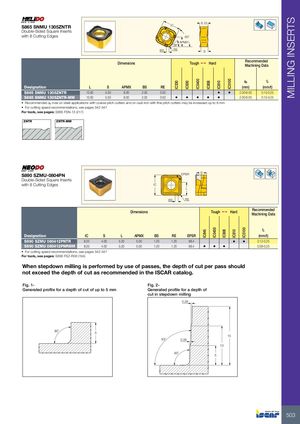

IC330 IC830 IC5400 IC845 IC808 IC5400 IC810 IC808 IC5100 IC810 IC5100 MILLING INSERTS 6.15 S865 SNMU 1305ZNTR IC Double-Sided Square Inserts with 8 Cutting Edges 65° APMX 38° BS RE S Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation L S APMX BS RE (mm) (mm/t) S865 SNMU 1305ZNTR 13.00 5.50 8.00 2.00 0.50 • • 2.00-6.00 0.15-0.25 S865 SNMU 1305ZNTR-MM 13.00 5.50 8.00 2.00 0.50 • • • • • 2.00-6.00 0.15-0.25 • Recommended ap max on steel applications with coarse pitch cutters and on cast iron with fine pitch cutters may be increased up to 8 mm • For cutting speed recommendations, see pages 542-547 For tools, see pages: S865 FSN-13 (217) ZNTR ZNTR-MM S890 SZMU-0804PN EPSR S Double-Sided Square Inserts with 8 Cutting Edges IC L BS RE Dimensions Tough 1 Hard RecommendedMachining Data fz Designation IC S L APMX BS RE EPSR (mm/t) S890 SZMU 080412PNTR 8.20 4.00 5.20 5.00 1.20 1.20 88.4 • • 0.12-0.25 S890 SZMU 080412PNRMM 8.20 4.00 5.20 5.00 1.20 1.20 88.4 • • • 0.08-0.25 • For cutting speed recommendations, see pages 542-547 For tools, see pages: S890 FSZ-R08 (194) When stepdown milling is performed by use of passes, the depth of cut per pass should not exceed the depth of cut as recommended in the ISCAR catalog. Fig. 1- Fig. 2- Generated profile for a depth of cut of up to 5 mm Generated profile for a depth of cut in stepdown milling 0.28 90˚ 5 15 93˚ 0.28 10 90˚ 5 503

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления