Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 167

Навигация

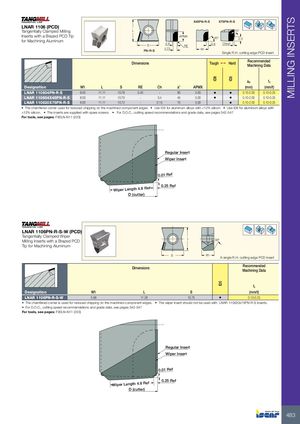

ID8 ID5 ID5 MILLING INSERTS X45PN-R-S X75PN-R-S LNAR 1106 (PCD) Tangentially Clamped Milling L 15° Inserts with a Brazed PCD Tipfor Machining Aluminum APMX 45° 2.0 S 2.6 RE 0.4 Chxa° PN-R-S 1.75 W1 Single R.H. cutting edge PCD insert Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation W1 L S RE Ch a° APMX (mm) (mm/t) LNAR 110604PN-R-S 6.00 11.11 10.76 0.40 - 90 5.00 • • 0.10-2.00 0.10-0.25 LNAR 110604X45PN-R-S 6.00 11.11 10.70 - 0.4 45 5.00 • • 0.10-2.00 0.10-0.25 LNAR 110620X75PN-R-S 6.00 11.11 10.72 - 0.15 75 5.00 • 0.10-2.00 0.10-0.25 • The chamfered corner used for reduced chipping on the machined component edges • Use ID5 for aluminum alloys with <12% silicon • Use ID8 for aluminum alloys with >12% silicon. • The inserts are supplied with spare screws. • For D.O.C., cutting speed recommendations and grade data, see pages 542-547 For tools, see pages: F90LN-N11 (203) Regular Insert Wiper Insert 0.01 Ref Wiper Length 4.6 Ref 0.25 Ref D (cutter) LNAR 1106PN-R-S-W (PCD) Tangentially Clamped WiperMilling Inserts with a Brazed PCD L 30º Tip for Machining Aluminum S W1 A single R.H. cutting edge PCD insert Dimensions RecommendedMachining Data fz Designation W1 L S (mm/t) LNAR 1106PN-R-S-W 5.98 11.26 10.75 • 0.10-0.25 • The chamfered corner is used for reduced chipping on the machined component edges. • The wiper insert should not be used with LNAR 110620x75PN-R-S inserts. • For D.O.C., cutting speed recommendations and grade data, see pages 542-547 For tools, see pages: F90LN-N11 (203) Regular Insert Wiper Insert 0.01 Ref Wiper Length 4.6 Ref 0.25 Ref D (cutter) 483

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления