Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 168

Навигация

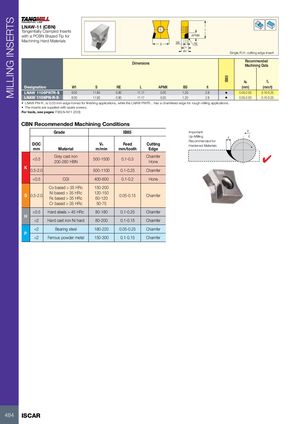

MILLING INSERTS IB85 LNAW-11 (CBN) Tangentially Clamped Inserts L with a PCBN Brazed Tip for APMX Machining Hard Materials S BS RE lt W1 Single R.H. cutting edge insert Dimensions RecommendedMachining Data ap fz Designation W1 S RE L APMX BS lt (mm) (mm/t) LNAW 1106PNTR-S 6.00 11.80 0.80 11.17 5.00 1.20 2.8 • 0.05-2.00 0.10-0.25 LNAW 1106PN-R-S 6.00 11.90 0.80 11.17 5.00 1.20 2.8 • 0.05-2.00 0.10-0.25 • LNAW PN-R.. is 0.03 mm edge-honed for finishing applications, while the LNAW PNTR... has a chamfered edge for rough milling applications. • The inserts are supplied with spare screws. For tools, see pages: F90LN-N11 (203) CBN Recommended Machining Conditions Grade IB85 Important: v Up-Milling f f Recommended for DOC Vc Feed Cutting Hardened Materials mm Material m/min mm/tooth Edge <0.5 Grey cast iron200-280 HBN 500-1500 0.1-0.3 ChamferHone K 0.5-2.0 500-1100 0.1-0.25 Chamfer <0.5 CGI 400-600 0.1-0.2 Hone Co based > 35 HRc 150-200 S 0.5-2.0 Ni based > 35 HRcFe based > 35 HRc120-15060-1200.05-0.15 Chamfer Cr based > 35 HRc 50-75 <0.5 Hard steels > 45 HRc 80-180 0.1-0.25 Chamfer H <2 Hard cast iron Ni hard 80-200 0.1-0.15 Chamfer <2 Bearing steel 180-220 0.05-0.25 Chamfer P <2 Ferrous powder metal 150-300 0.1-0.15 Chamfer 484 ISCAR

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления