Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 159

Навигация

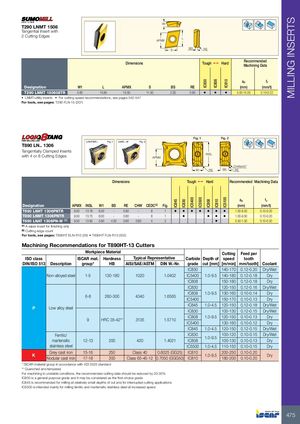

IC845 IC830 IC5400 IC5500 IC830 IC808 IC808IC810 IC810IC5100 MILLING INSERTS W1 T290 LNMT 1506 Tangential Insert with 2 Cutting Edges L APMX S BS RE Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation W1 L APMX S BS RE (mm) (mm/t) T290 LNMT 150608TR 5.60 15.90 15.00 11.50 2.00 0.80 • • • 5.00-15.00 0.10-0.22 • LNMT-utility inserts • For cutting speed recommendations, see pages 542-547 For tools, see pages: T290 FLN-15 (207) Fig. 1 Fig. 2 T890 LN.. 1306 Tangentially Clamped Inserts with 4 or 8 Cutting Edges INSLAPMX CHWx45° W1 RE BS RE Dimensions Tough 1 Hard Recommended Machining Data ap fz Designation APMX INSL W1 BS RE CHW CEDC(2) Fig. (mm) (mm/t) T890 LNHT 1306PNTR 9.50 13.78 6.00 - 0.80 - 8 1 • • • • • • • 1.00-9.50 0.10-0.20 T890 LNMT 1306PNTR 9.50 13.75 6.00 - 0.80 - 8 1 • • • • 1.00-9.50 0.10-0.20 T890 LNAT 1306PN-W (1) 9.50 13.92 5.90 4.30 0.60 0.60 4 2 • 0.50-1.00 0.10-0.20 (1) A wiper insert for finishing only (2) Cutting edge count For tools, see pages: T890HT ELN-R13 (29) • T890HT FLN-R13 (202) Machining Recommendations for T890HT-13 Cutters Workpiece Material Cutting Feed per ISO class ISCAR mat. Hardness Typical Representative Carbide Depth of speed tooth DIN/ISO 513 Description group* HB AISI/SAE/ASTM DIN W.-Nr. grade cut [mm] [m/min] mm/tooth] Coolant IC830 140-170 0.12-0.20 Dry/Wet Non-alloyed steel 1-5 130-180 1020 1.0402 IC5400 1.0-9.5 140-180 0.12-0.18 Dry IC808 150-180 0.12-0.18 Dry IC830 120-150 0.12-0.16 Dry/Wet 6-8 260-300 4340 1.6565 IC808 1.0-9.5 130-160 0.10-0.14 DryIC5400150-1700.10-0.13Dry P Low alloy steel IC845 1.0-4.5 120-150 0.12-0.18 Dry/WetIC830100-1300.12-0.15Dry/Wet IC808 1.0-9.5 120-150 0.10-0.13 Dry 9 HRC 35-42** 3135 1.5710 IC5400 130-160 0.10-0.12 Dry IC845 1.0-4.5 120-150 0.12-0.15 Dry/Wet Ferritic/martensitic 12-13 200 420 1.4021 IC830IC808 1.0-9.5 100-120100-130 0.10-0.150.10-0.13Dry/WetDry stainless steel IC5500 1.0-4.5 110-150 0.10-0.15 Dry K Grey cast iron 15-16Nodular cast iron17-18250200Class 40 0.6025 (GG25) IC810Class 65-45-120.7050 (GGG50)IC8101.0-9.5200-250180-2000.10-0.200.10-0.20Dry * ISCAR material group in accordance with VDI 3323 standard ** Quenched and tempered For machining in unstable conditions, the recommended cutting data should be reduced by 20-30% IC830 is a general purpose grade and it may be considered as the first-choice grade IC845 is recommended for milling at relatively small depths of cut and for interrupted cutting applications IC5500 is intended mainly for milling ferritic and martensitic stainless steel at increased speed 475

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления