Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 157

Навигация

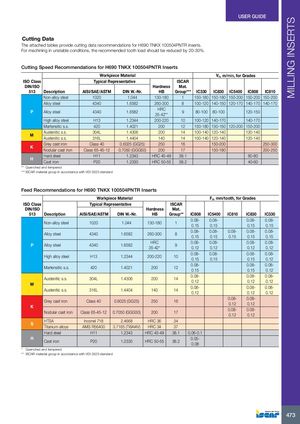

MILLING INSERTS USER GUIDE Cutting Data The attached tables provide cutting data recommendations for H690 TNKX 100504PNTR inserts. For machining in unstable conditions, the recommended tooth load should be reduced by 20-30%. Cutting Speed Recommendations for H690 TNKX 100504PNTR Inserts Workpiece Material Vc, m/min, for Grades ISO Class Typical Representative ISCAR DIN/ISO Hardness Mat. 513 Description AISI/SAE/ASTM DIN W.-Nr. HB Group*** IC330 IC830 IC5400 IC808 IC810 Non-alloy steel 1020 1.044 130-180 1 150-180 150-180 150-200 150-200 150-200 Alloy steel 4340 1.6582 260-300 8 100-120 140-150 120-170 140-170 140-170 P Alloy steel 4340 1.6582 HRC35-42** 9 80-100 80-100 120-150 High alloy steel H13 1.2344 200-220 10 100-120 140-170 140-170 Martensitic s.s. 420 1.4021 200 12 150-180 150-150 120-200 150-200 Austenitic s.s. 304L 1.4306 200 14 100-140 120-140 120-140 M Austenitic s.s. 316L 1.4404 140 14 100-140 120-140 120-140 K Grey cast ironNodular cast ironClass 40 0.6025 (GG25)Class 65-45-120.7050 (GGG50)2502001617150-200150-180 250-300200-250 H Hard steelCast iron H11 1.2343 HRC 45-49 38.1P201.2330HRC 50-5538.2 60-8040-60 ** Quenched and tempered *** ISCAR material group in accordance with VDI 3323 standard Feed Recommendations for H690 TNKX 100504PNTR Inserts Workpiece Material Fz, mm/tooth, for Grades ISO Class Typical Representative ISCAR DIN/ISO Hardness Mat. 513 Description AISI/SAE/ASTM DIN W.-Nr. HB Group** IC808 IC5400 IC810 IC830 IC330 Non-alloy steel 1020 1.044 130-180 1 0.08- 0.08-0.150.15 0.08- 0.08-0.150.15 Alloy steel 4340 1.6582 260-300 8 0.08- 0.08- 0.08- 0.08- 0.08-0.150.150.150.150.15 P Alloy steel 4340 1.6582 HRC35-42* 9 0.08- 0.08-0.120.12 0.08- 0.08-0.120.12 High alloy steel H13 1.2344 200-220 10 0.08- 0.08-0.150.15 0.08- 0.08-0.150.12 Martensitic s.s. 420 1.4021 200 12 0.08-0.15 0.08- 0.08-0.150.12 Austenitic s.s. 304L 1.4306 200 14 0.08-0.12 0.08- 0.08-0.120.12 M Austenitic s.s. 316L 1.4404 140 14 0.08-0.12 0.08- 0.08-0.120.12 Grey cast iron Class 40 0.6025 (GG25) 250 16KNodular cast ironClass 65-45-120.7050 (GGG50)200170.08-0.08-0.120.120.08-0.08-0.120.12 S HTSATitanium alloys Inconel 718 2.4668 HRC 36 34AMS R564003.7165 (Ti6Al4V)HRC 3437 Hard steel H11 1.2343 HRC 45-49 38.1 0.06-0.1 H Cast iron P20 1.2330 HRC 50-55 38.2 0.05-0.08 * Quenched and tempered ** ISCAR material group in accordance with VDI 3323 standard 473

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления