Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 138

Навигация

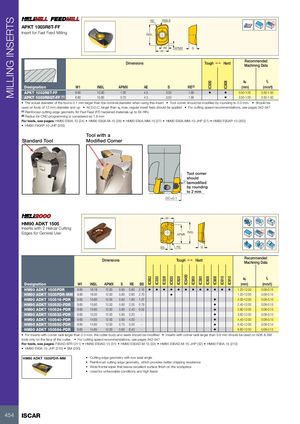

MILLING INSERTS IC882 IC330 IC328 IC830 IC928 IC5400 IC950 IC380 IC830IC808 IC908 IC810 IC808 IC910 RE RE9.9 Rd° APKT 1003R8T-FF Insert for Fast Feed Milling INSL AE APMX S W1 Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation W1 INSL APMX AE S RE(2) (mm) (mm/t) APKT 1003R8T-FF 6.60 10.80 1.00 4.5 3.50 1.90 • • 0.50-1.00 0.50-1.50 APKT 1003R8GT-FF (1) 6.60 10.80 0.70 4.5 3.50 1.90 • 0.50-1.00 0.50-1.50 • The actual diameter of the tool is 0.1 mm larger than the nominal diameter when using this insert • Tool corner should be modified by rounding to 2.0 mm. • Should be used on tools of 12 mm diameter and up • At D.O.C. larger than ap max, regular insert feed should be applied • For cutting speed recommendations, see pages 542-547 (1) Reinforced cutting-edge geometry for Fast Feed (FF) hardened materials up to 64 HRc (2) Radius for CNC programming is considered as 1.8 mm For tools, see pages: HM90 E90A-10 (24) • HM90 E90A-M-10 (28) • HM90 E90A-MM-10 (27) • HM90 E90A-MM-10-JHP (27) • HM90 F90AP-10 (200) • HM90 F90AP-10-JHP (200) Tool with a Standard Tool Modified Corner Tool corner should 3°bemodified by rounding to 2 mm DC+0.1 W1 HM90 ADKT 1505 Inserts with 2 Helical Cutting Rd° Edges for General Use APMX INSL BS RE S Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation W1 INSL APMX S RE BS (mm) (mm/t) HM90 ADKT 1505PDR 9.65 16.18 12.00 5.85 0.80 2.16 • • • • • • • • • • • • 1.20-12.00 0.08-0.15 HM90 ADKT 1505PDR-MM 9.60 16.00 12.00 5.80 0.80 2.70 • 1.20-12.00 0.08-0.15 HM90 ADKT 150516-PDR 9.65 15.60 12.00 5.92 1.60 1.37 • 2.00-12.00 0.08-0.15 HM90 ADKT 150520-PDR 9.65 15.60 12.00 5.90 2.00 0.79 • 2.40-12.00 0.08-0.15 HM90 ADKT 150524-PDR 9.65 15.60 12.00 5.80 2.40 0.52 • 2.80-12.00 0.08-0.15 HM90 ADKT 150532-PDR 9.65 15.20 12.00 5.85 3.20 - • 3.60-12.00 0.08-0.15 HM90 ADKT 150540-PDR 9.65 14.83 12.00 5.80 4.00 - • 4.40-12.00 0.08-0.15 HM90 ADKT 150550-PDR 9.65 14.85 12.00 5.75 5.00 - • 5.40-12.00 0.08-0.15 HM90 ADKT 150564-PDR 9.65 14.85 12.00 5.65 6.40 - • 6.80-12.00 0.08-0.15 • For inserts with corner radii larger than 2.0 mm, the cutter body and seats should be modified • Inserts with corner radii larger than 0.8 mm should be used on ADK & SM tools only on the face of the cutter. • For cutting speed recommendations, see pages 542-547 For tools, see pages: F90AD-SFR (211) • HM90 E90AD-15 (31) • HM90 E90AD-M-15 (32) • HM90 E90AD-M-15-JHP (32) • HM90 F90A-15 (210) • HM90 F90A-15-JHP (210) • SM (250) HM90 ADKT 1505PDR-MM • Cutting edge geometry with low axial angle • Reinforced cutting edge geometry, which provides better chipping resistance • Wide frontal wiper that leaves excellent surface finish on the workpiece • Used for unfavorable conditions and high feeds 454 ISCAR

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления