Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 134

Навигация

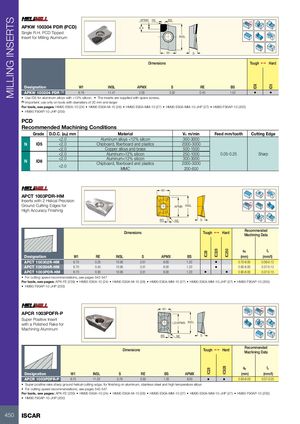

MILLING INSERTS IC28 IC28 IC328 IC250IC928 ID8 ID5 APMX RE BS Rd° APKW 100304 PDR (PCD) 4.4 Single R.H. PCD Tipped Insert for Milling Aluminum lNSL W1 S Dimensions Tough 1 Hard Designation W1 INSL APMX S RE BS APKW 100304 PDR (1) 6.76 11.47 2.00 3.50 0.40 1.52 • • • Use ID5 for aluminum alloys with <12% silicon. • The inserts are supplied with spare screws. (1) Important: use only on tools with diameters of 20 mm and larger For tools, see pages: HM90 E90A-10 (24) • HM90 E90A-M-10 (28) • HM90 E90A-MM-10 (27) • HM90 E90A-MM-10-JHP (27) • HM90 F90AP-10 (200) • HM90 F90AP-10-JHP (200) PCD Recommended Machining Conditions Grade D.O.C. (ap) mm Material Vc m/min Feed mm/tooth Cutting Edge <2.0 Aluminum alloys <12% silicon 300-3000 N ID5 <2.0 Chipboard, fiberboard and plastics 2000-3000 <2.0 Copper alloys and brass 500-1500 <2.0 Aluminum>12% silicon 250-1000 0.05-0.25 Sharp N ID8 <2.0<2.0 Aluminum<12% silicon 300-3000Chipboard, fiberboard and plastics2000-3000MMC200-600 W1 APCT 1003PDR-HM Inserts with 2 Helical Precision Rd° Ground Cutting Edges for APMX INSL High Accuracy Finishing BS RE S Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation W1 RE INSL S APMX BS (mm) (mm/t) APCT 100302R-HM 6.70 0.25 10.95 3.51 8.00 1.20 • 0.70-8.00 0.06-0.12 APCT 100304R-HM 6.70 0.45 10.95 3.51 8.00 1.20 • 0.90-8.00 0.07-0.12 APCT 1003PDR-HM 6.70 0.50 10.95 3.51 8.00 1.20 • • 0.90-8.00 0.07-0.15 • For cutting speed recommendations, see pages 542-547 For tools, see pages: APK-FE (239) • HM90 E90A-10 (24) • HM90 E90A-M-10 (28) • HM90 E90A-MM-10 (27) • HM90 E90A-MM-10-JHP (27) • HM90 F90AP-10 (200) • HM90 F90AP-10-JHP (200) W1 Rd° APCR 1003PDFR-P Super Positive Insert with a Polished Rake for LE/APMX INSL Machining Aluminum BS RE S Dimensions Tough 1 Hard RecommendedMachining Data ap fz Designation W1 INSL S RE BS APMX (mm) (mm/t) APCR 1003PDFR-P 6.70 11.20 3.76 0.50 1.20 8.00 • • 0.90-8.00 0.07-0.25 • Super positive rake sharp ground helical cutting edge, for finishing on aluminum, stainless steel and high temperature alloys • For cutting speed recommendations, see pages 542-547 For tools, see pages: APK-FE (239) • HM90 E90A-10 (24) • HM90 E90A-M-10 (28) • HM90 E90A-MM-10 (27) • HM90 E90A-MM-10-JHP (27) • HM90 F90AP-10 (200) • HM90 F90AP-10-JHP (200) 450 ISCAR

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления