Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 121

Навигация

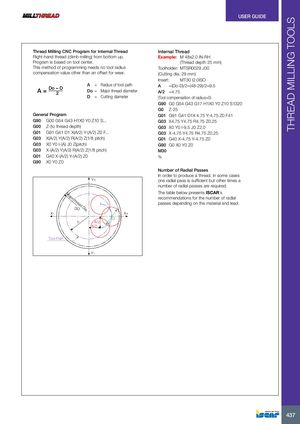

THREAD MILLING TOOLS USER GUIDE Thread Milling CNC Program for Internal Thread Internal Thread Right-hand thread (climb milling) from bottom up. Example: M 48x2.0 IN-RH Program is based on tool center. (Thread depth 25 mm) This method of programming needs no tool radius Toolholder: MTSR0029 J30 compensation value other than an offset for wear. (Cutting dia. 29 mm) Insert: MT30 I2.0ISO A = Do –2 D A = Radius of tool path A =(Do-D)/2=(48-29)/2=9.5Do =Major thread diameterA/2=4.75 D = Cutting diameter (Tool compensation of radius=0) G90 G0 G54 G43 G17 H1X0 Y0 Z10 S1320 G0 Z-25 General Program G01 G91 G41 D1X 4.75 Y-4.75 Z0 F41 G90 G00 G54 G43 H1X0 Y0 Z10 S... G03 X4.75 Y4.75 R4.75 Z0.25 G00 Z-(to thread depth) G03 X0 Y0 I-9.5 J0 Z2.0 G01 G91 G41 D1 X(A/2) Y-(A/2) Z0 F... G03 X-4.75 Y4.75 R4.75 Z0.25 G03 X(A/2) Y(A/2) R(A/2) Z(1/8 pitch) G01 G40 X-4.75 Y-4.75 Z0 G03 X0 Y0 I-(A) J0 Z(pitch) G90 G0 X0 Y0 Z0 G03 X-(A/2) Y(A/2) R(A/2) Z(1/8 pitch) M30 G01 G40 X-(A/2) Y-(A/2) Z0 % G90 X0 Y0 Z0 Number of Radial Passes In order to produce a thread, in some cases Y+ one radial pass is sufficient but other times a number of radial passes are required. Major thread DO Dia. The table below presents ISCAR'srecommendations for the number of radialpasses depending on the material and lead. X- X+ D A A/2 A/2 Tool Path Y- 437

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления