Общий каталог Harlingen 2024 - страница 170

Навигация

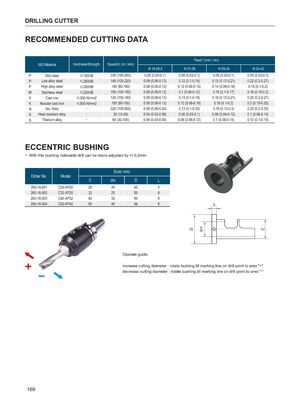

DRILLING CUTTER RECOMMENDED CUTTING DATA Feed f (mm / rev) ISO Material Hardness/Strength SpeedVc ( m / min) HB ^180 280HB ^280HB ^250HB ^ N/mm2 ^ 350 ^ 800 N/mm2 230 140 ( 100-220) 140 ( 80-180) 150 ( 100-180) 120 (100-180) 100 ( 80-150) 220 (100-800) 30 (15-50) 60 (30-100) 014-20.5 p Mild steel Low alloy steel High alloy steel M K K N S S Stainless steel Cast iron Nodular cast iron Alu. Alloy Heat resistant alloy Titanium alloy P P (0.03-0.1) ( 150-260) 0.05 0.09 (0.06-0.13) 0.08 (0.05-0.12) 0.08 (0.05-0.12) 0.09 (0.06-0.13) 0.09 (0.06-0.13) 0.09 (0.06-0.20) 0.04 (0.02-0.06) 0.06 (0.04-0.08) 021-28 029-34 (0.03-0.1) 0.05 0.12 (0.1-0.18) 0.12 (0.06-0.15) 0.1 (0.06-0.12) 0.13 (0.1-0.18) 0.12 (0.08-0.16) 0.13 (0.1-0.25) 0.06 (0.03-0.1) 0.08 (0.06-0.12) 0 34-42 (0.03-0.1) 0.05 0.15 (0.13-0.21) 0.14 (0.09- 0.18) 0.15 (0.1-0.17) 0.18 (0.13- 0.21) 0.16 (0.1-0.2) 0.18 (0.13-0.3) 0.08 (0.04- 0.12) 0.1 (0.08-0.15) 0.05 (0.03-0.1) 0.22 (0.2-0.27) 0.15 (0.1-0.2) 0.18 (0.15-0.2) 0.25 (0.2-0.27) 0.2 (0.15-0.25) 0.25 (0.2-0.35) 0.1 (0.06-0.14) 0.12 (0.1-0.15) ECCENTRIC BUSHING • With this bushing indexable drill can be micro adjusted by +/-0.2mm Size( mm) Order No. Model dm 260-16-001 260-16-002 260-16-003 260-16-004 C 25- XP20 C32- XP25 C40- XP32 C50- XP40 25 32 40 50 20 25 32 40 42 50 60 66 5 8 8 8 o E -o O K u Operate guide: increase cutting diameter : rotate bushing till marking line on drill point to areo "+" decrease cutting diameter : rotate bushing till marking line on drill point to areo 169

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования Каталог Harlingen системы нулевого базирования

Каталог Harlingen системы нулевого базирования Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые) Каталог Harlingen статические держатели режущих инструментов блочного типа

Каталог Harlingen статические держатели режущих инструментов блочного типа