Общий каталог Harlingen 2024 - страница 169

Навигация

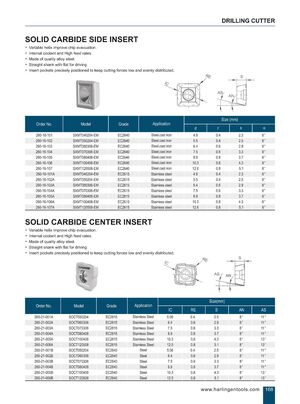

DRILLING CUTTER SOLID CARBIDE SIDE INSERT • Variable helix improve chip evacuation . • Internal coolant and High feed rates. • Made of quality alloy steel. • Straight shank with flat for driving • Insert pockets precisely positioned to keep cutting forces low and evenly distributed. % S lc AS 7 SXMT040204-EM SXMT050204-EM SXMT060306-EM SXMT070306-EM SXMT080408-EM SXMT100408-EM SXMT120508 -EM SXMT040204-EM SXMT050204-EM SXMT060306-EM SXMT070306-EM SXMT080408 -EM SXMT100408 -EM SXMT120508 -EM EC2640 EC2640 EC2640 EC2640 EC2640 EC2640 EC2640 EC2615 EC2615 EC2615 EC2615 EC2615 EC2615 EC2615 Steel,cast iron Steel,cast iron Steel,cast iron Steel,cast iron Steel,cast iron Steel,cast iron Steel,cast iron Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel Stainless steel ' " \ i 260-16-101 260-16-102 260-16-103 260-16-104 260-16-105 260-16-106 260-16-107 260-16-101A 260-16-102A 260-16-103A 260-16-104A 260-16-105A 260-16-106A 260-16-107A AN/ 4.9 5.5 6.4 7.5 8.9 10.3 12.6 4.9 5.5 6.4 7.5 8.9 10.3 12.6 2.3 2.5 2.9 3.3 3.7 4.3 5.1 2.3 2.5 2.9 3.3 3.7 4.3 5.1 0.4 0.4 0.6 0.6 0.8 0.8 0.8 0.4 0.4 0.6 0.6 0.8 0.8 0.8 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° SOLID CARBIDE CENTER INSERT • Variable helix improve chip evacuation . • Internal coolant and High feed rates. • Made of quality alloy steel. • Straight shank with flat for driving • Insert pockets precisely positioned to keep cutting forces low and evenly distributed. S AS 260-21-001 A 260-21-002 A 260-21-003A 260-21-004A 260-21-005A 260-21-006A 260-21-001B 260-21-002B 260-21-003B 260-21-004B 260-21- 005B 260-21-006B SOCT050204 SOCT060306 SOCT070306 SOCT080408 SOCT100408 SOCT120508 SOCT050204 SOCT060306 SOCT070306 SOCT080408 SOCT100408 SOCT120508 EC 2615 EC 2615 EC 2615 EC 2615 EC 2615 EC 2615 EC 2640 EC2640 EC 2640 EC 2640 EC 2640 EC 2640 Stainless Steel Stainless Steel Stainless Steel Stainless Steel Stainless Steel Stainless Steel Steel Steel Steel Steel Steel Steel 5.06 6.4 7.5 8.9 10.3 12.5 5.06 6.4 7.5 8.9 10.3 12.5 0.4. 0.6 0.6 0.8 0.8 0.8 0.4. 0.6 0.6 0.8 0.8 0.8 2.5 2.9 3.3 3.7 4.3 5.1 2.5 2.9 3.3 3.7 4.3 5.1 / AN 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° 8° www. harlingentools . com 11 ° 11 ° 11 ° 11 ° 13 ° 13 ° 11 ° 11 ° 11 ° 11 ° 13 ° 13 ° 168

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования Каталог Harlingen системы нулевого базирования

Каталог Harlingen системы нулевого базирования Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые) Каталог Harlingen статические держатели режущих инструментов блочного типа

Каталог Harlingen статические держатели режущих инструментов блочного типа