Общий каталог Harlingen 2024 - страница 130

Навигация

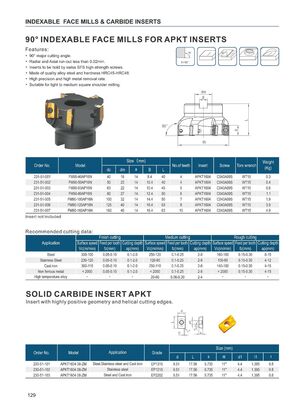

INDEXABLE FACE MILLS & CARBIDE INSERTS 90 ° INDEXABLE FACE MILLS FOR APKT INSERTS Features: Kr S ' • 90° major cutting angle. • Radial and Axial run-out less than 0.02 mm . • Inserts to be hold by swiss SFS high strength screws. • Made of quality alloy steel and hardness HRC45-HRC48. • High precision and high metal removal rate. • Suitable for light to medium square shoulder milling. Kr=90 ° dm B B) dc Order No . Insert Screw Torx wrench Weight (Kg) APKT1604 APKT1604 APKT1604 APKT1604 APKT1604 APKT1604 APKT1604 C040A09S C040A09S C040A09S C040A09S C040A09S C040A09S C040A09S WT15 WT15 WT15 WT15 WT15 WT15 WT15 0.3 0.4 0.6 1.1 1.9 3.9 4.9 No.of teeth 231-51-001 231- 51-002 231-51-003 231-51-004 231-51-005 231-51-006 231-51-007 FM90-40AP16N FM90-50AP16N FM90-63AP16N FM90-80AP16N FM90-100AP16N FM90-125AP16N FM90-160AP16N 100 125 160 Insert not included Recommended cutting data : Finish cutting Medium cutting Rough cutting Surface speed Feed per tooth | Cutting depth | Surface speed | Feed per tooth | Cutting depth| Surface speed | Feed per tooth | Cutting depth fz(mm) fz(mm) fz(mm) ap (mm) Vc(m/min) Vc(m/min) Vc(m/min) ap(mm) ap(mm) Application 300-100 230-120 300-110 < 2000 Steel Stainless Steel Cast iron Non ferrous metal High temperature alloy 0.05-0.10 0.05-0.10 0.05-0.10 0.05-0.10 0.1-2.0 0.1-2.0 0.1-2.0 0.1-2.0 250-120 120-60 250-110 < 2000 20-60 0.1-0.25 0.1-0.25 0.1-0.25 0.1-0.25 0.06-0.20 160-100 100-60 140-100 < 2000 2 -8 2 -8 2 -8 2 -8 2-4 0.15-0.30 0.15-0.30 0.15-0.30 0.15-0.30 8-15 4-12 4-15 4-15 SOLID CARBIDE INSERT APKT Insert with highly positive geometry and helical cutting edges . d 5 ^Tv “ 11 Model Application Grade 230-51-101 230-51-102 230-51-103 APKT1604 08-ZM APKT1604 08-ZM APKT1604 08-ZM Steel Stainless steel and Cast iron Stainless steel Steel and Cast iron EP1315 EP1215 EP2202 129 L X s. Size (mm) Order No. . TJ r 9.51 9.51 9.51 17.56 17.56 17.56 5.735 5.735 5.735 11° 11° 11° 4.4 4.4 4.4 1.395 1.395 1.395 0.8 0.8 0.8

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования Каталог Harlingen системы нулевого базирования

Каталог Harlingen системы нулевого базирования Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые) Каталог Harlingen статические держатели режущих инструментов блочного типа

Каталог Harlingen статические держатели режущих инструментов блочного типа