Общий каталог FANAR 2021 - страница 317

Навигация

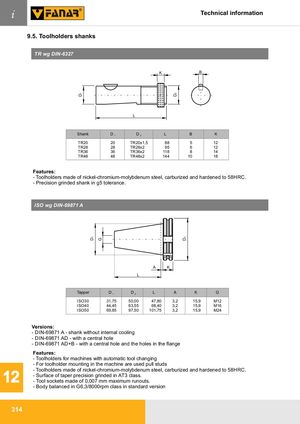

D1 D1 G D2 D2 i Technical information 9.5. Toolholders shanks TR wg DIN-6327 K B L Shank D1 D2 L B K TR20 20 TR20x1,5 88 5 12 TR28 28 TR28x2 95 6 12 TR36 36 TR36x2 118 8 14 TR48 48 TR48x2 144 10 18 Features: - Toolholders made of nickel-chromium-molybdenum steel, carburized and hardened to 58HRC. - Precision grinded shank in g5 tolerance. ISO wg DIN-69871 A A K L Tapper D1 D2 L A K G ISO30 31,75 50,00 47,80 3,2 15,9 M12 ISO40 44,45 63,55 68,40 3,2 15,9 M16 ISO50 69,85 97,50 101,75 3,2 15,9 M24 Versions: - DIN-69871 A - shank without internal cooling - DIN-69871 AD - with a central hole - DIN-69871 AD+B - with a central hole and the holes in the flange Features: - Toolholders for machines with automatic tool changing - For toolholder mounting in the machine are used pull studs - Toolholders made of nickel-chromium-molybdenum steel, carburized and hardened to 58HRC. 12 - Surface of taper precision grinded in AT3 class.- Tool sockets made of 0,007 mm maximum runouts. - Body balanced in G6,3/8000rpm class in standard version 314

Общий каталог FANAR 2018

Общий каталог FANAR 2018 Каталог FANAR цельные твердосплавные фрезы

Каталог FANAR цельные твердосплавные фрезы