Каталог Duemmel общий 2022 - страница 209

Навигация

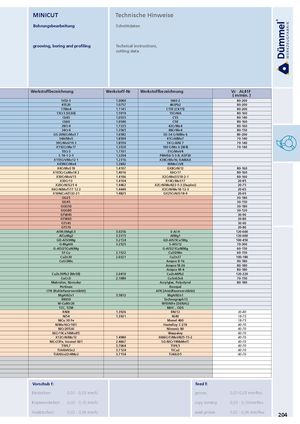

MINICUT Technische Hinweise Bohrungsbearbeitung Schnittdaten grooving, boring and profiling Technical instructions, cutting data Werkstoffbezeichnung Werkstoff-Nr Werkstoffbezeichnung Vc AL41F ( m/min. ) St52-3 1.0060 St60-2 80-200 45S20 1.0757 46SPb2 80-200 17Mn4 1.1141 C15E (CK15) 80-200 13Cr3 (EC60) 1.5919 15CrNi6 80-160 Ck45 1.0535 C55 80-140 Ck60 1.0540 C50 80-160 28Cr4 1.7225 42CrMo4 80-160 34Cr4 1.3565 48CrMo4 80-150 GS-20NiCrMo3 7 1.6582 GS-34 CrNiMo 6 80-200 34AlMo5 1.8509 41CrAlMo7 70-140 39CrMoV19 3 1.8550 34 CrAlNi 7 70-140 X192CrMo17 1.3520 100 CrMn 6 (W4) 70-140 55Cr3 1.7701 51CrMoV4 S 18-1-2-5 1.3294 PMHS6-5-3-8; ASP30 X155CrVMo12 1 1.2316 X38CrMo16; RAMAX X45NiCrMo4 1.2842 90MnCrV8 X4CrMoS18 1.4107 GX8CrNi12 80-160 X105CrCoMo18 2 1.4016 X6Cr17 80-160 X50CrMoV15 1.4106 X2CrMoSiS18-2-1 80-160 X30Cr13 1.4104 X14CrMoS17 20-85 X20CrNiSi25 4 1.4462 X2CrNiMoN22-5-3 (Duplex) 20-75 X6CrNiMoTi17 12 2 1.4449 X3CrNiMo18-12-3 20-65 X10NiCrAlTi32-21 1.4825 GX25CrNiSi18-9 20-65 GG25 30-180 GG45 30-150 GGG50 30-180 GGG80 30-120 GTW45 30-90 GTW65 20-80 GTS45 30-90 GTS70 20-80 Al99,9Mg0,5 3.0256 E-Al H 120-600 AlCuMg2 3.3315 AlMg1 120-600 GD-AlSi9Mg 3.2134 GD-AlSi5Cu1Mg 100-450 G-MgAl6 3.2525 S-AlSi12 70-300 G-AlSi25CuNiMg G-AlSi21CuNiMg 60-150 SF-Cu 2.1522 CuSl2Mn 60-150 CuZn30 2.0321 CuZn37 100-180 CuSi3Mn Ampco 8-16 90-180 Ampco18-26 80-180 Ampco M-4 80-180 CuZn39Pb2 (Ms58) 2.0410 CuZn44Pb2 120-220 CuCrZr 2.1080 CuSn6Zn6 70-150 Makrolon, Novodur Acrylglas, Polystyrol 80-180 Pertinax Resopal CFK (Kohlefaserverstärkt) AFK (Amidfaserverstärkt) MgAl6Zn1 3.5812 MgAl8Zn1 R8650 Technograph15 W-Cu80/20 W93NiFe (DENAL) TZC, TZM MHC , ODS RNi8 1.3926 RNi12 30-80 Ni54 1.3921 Ni49 18-75 NiCu 30 Fe Monel 400 18-75 NiMo16Cr16Ti Hastelloy C-276 40-70 NiCr20TiAl Nimonic 80 40-70 NiCr19Co14Mo4Ti Waspaloy 40-70 X12CrNiMo12 1.4980 X6NiCrTiMoVB25-15-2 40-70 NiCr23Fe, Inconel 601 2.4667 SG-NiCr19NbMoTi 40-70 Ti99,7 3.7064 Ti99,5 40-70 TiAl6V6Sn2 3.7124 TiCu2 40-70 TiAl6Sn2Zr4Mo2 3.7154 TiAl6Zr5 40-70 Vorschub f: feed f: Einstechen: 0,01 - 0,03 mm/U groove: 0,01-0,03 mm/Rev. Kopierendrehen: 0,03 - 0,10 mm/U copy turning: 0,03 - 0,10mm/Rev. Axialstechen: 0,02 - 0,06 mm/U axial groove: 0,02 - 0,06 mm/Rev. 204

Общий каталог Dümmel 2014

Общий каталог Dümmel 2014 Каталог Dümmel дополнение 2017

Каталог Dümmel дополнение 2017 Каталог Dümmel дополнение 2018

Каталог Dümmel дополнение 2018 Общий каталог Dümmel 2015

Общий каталог Dümmel 2015