Общий каталог Dijet 2018 - страница 539

Навигация

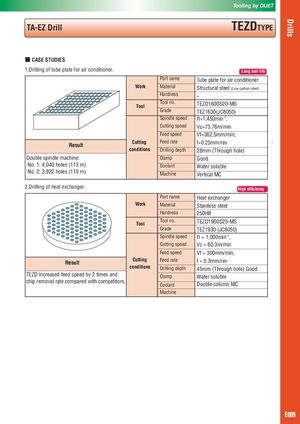

Tooling by DIJET TA-EZ Drill TEZDTYPE ■ CASE STUDIES 1.Drilling of tube plate for air conditioner. Long tool life Part name Tube plate for air conditioner Work Material Structural steel (Low carbon steel) Hardness − Tool no.Tool TEZD1600S20-MS Grade TEZ1630(JC8050) Spindle speed n=1,450min-1, Cutting speed Vc=73.76m/min Feed speed Vf=362.5mm/min, Result Cutting Feed rate f=0.25mm/rev conditions Drilling depth 28mm (Through hole) Double spindle machine: Clamp Good No. 1: 4,040 holes (113 m) Coolant Water soluble No. 2: 3,922 holes (110 m) Machine Vertical MC 2.Drilling of heat exchanger. High efficiency Part name Heat exchanger Work Material Stainless steel Hardness 250HB Tool Tool no. TEZD1900S25-MS Grade TEZ1930 (JC8050) Spindle speed n = 1,000min-1, Cutting speed Vc = 60.3m/min Feed speed Vf = 300mm/min, Result Cutting Feed rate f = 0.3mm/rev conditions Drilling depth 45mm (Through hole) Good TEZD increased feed speed by 2 times and Clamp Water soluble chip removal rate compared with competitors. Coolant Double column MC Machine E009

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском