Общий каталог Dijet 2018 - страница 538

Навигация

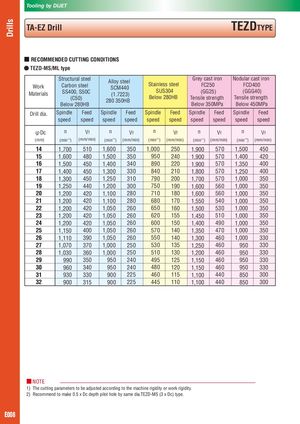

Tooling by DIJET TA-EZ Drill TEZDTYPE ■ RECOMMENDED CUTTING CONDITIONS ● TEZD-MS/ML type Structural steel Alloy steelWorkCarbon steelMaterialsSS400, S50C(C50)Below 280HBSCM440(1.7223)280 350HBGrey cast ironNodular cast ironStainless steelFC250FCD400SUS304(GG25)(GGG40)Below 280HBTensile strengthTensile strengthBelow 350MPaBelow 450MPa Drill dia. Spindle Feed Spindle Feed Spindle Feed Spindle Feed Spindle Feed speed speed speed speed speed speed speed speed speed speed φDc n Vf n Vf n Vf n Vf n Vf (mm) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 14 1,700 510 1,600 350 1,000 250 1,900 570 1,500 450 15 1,600 480 1,500 350 950 240 1,900 570 1,400 420 16 1,500 450 1,400 340 890 220 1,900 570 1,350 400 17 1,400 450 1,300 330 840 210 1,800 570 1,250 400 18 1,300 450 1,250 310 790 200 1,700 570 1,000 350 19 1,250 440 1,200 300 750 190 1,600 560 1,000 350 20 1,200 420 1,100 280 710 180 1,600 560 1,000 350 21 1,200 420 1,100 280 680 170 1,550 540 1,000 350 22 1,200 420 1,050 260 650 160 1,500 530 1,000 350 23 1,200 420 1,050 260 620 155 1,450 510 1,000 350 24 1,200 420 1,050 260 600 150 1,400 490 1,000 350 25 1,150 400 1,050 260 570 140 1,350 470 1,000 350 26 1,110 390 1,050 260 550 140 1,300 460 1,000 330 27 1,070 370 1,000 250 530 135 1,250 460 950 330 28 1,030 360 1,000 250 510 130 1,200 460 950 330 29 990 350 950 240 495 125 1,150 460 950 330 30 960 340 950 240 480 120 1,150 460 950 330 31 930 330 900 225 460 115 1,100 440 850 300 32 900 315 900 225 445 110 1,100 440 850 300 ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) Recommend to make 0.5 x Dc depth pilot hole by same dia.TEZD-MS (3 x Dc) type. E008

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском