Общий каталог Dijet 2018 - страница 514

Навигация

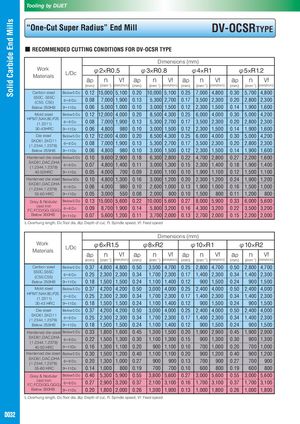

Solid Carbide End Mills Tooling by DIJET “One-Cut Super Radius” End Mill DV-OCSRTYPE ■ RECOMMENDED CUTTING CONDITIONS FOR DV-OCSR TYPE Dimensions (mm) WorkMaterials L/Dc φ2×R0.5 φ3×R0.8 φ4×R1apnVfapnVfapnVf φ5×R1.2apn Vf (mm) (mm-1) (mm/min) (mm) (mm-1) (mm/min) (mm) (mm-1) (mm/min) (mm) (mm-1) (mm/min) Carbon steel Below5 Dc 0.12 15,000 5,100 0.20 10,000 5,100 0.25 7,000 4,800 0.30 5,700 4,800 S50C, S55C(C50, C55)6~8 Dc 0.08 7,000 1,900 0.13 5,300 2,700 0.17 3,500 2,300 0.20 2,800 2,300 Below 250HB 9~11Dc 0.06 5,000 1,000 0.10 3,000 1,500 0.12 2,300 1,500 0.14 1,900 1,600 Mold steel Below5 Dc 0.12 12,000 4,000 0.20 8,500 4,300 0.25 6,000 4,000 0.30 5,000 4,200 HPM7,NAK80,P20(1.2311)6~8 Dc 0.08 7,000 1,900 0.13 5,300 2,700 0.17 3,500 2,300 0.20 2,800 2,300 30-43HRC 9~11Dc 0.06 4,800 980 0.10 3,000 1,500 0.12 2,300 1,500 0.14 1,900 1,600 Die steel Below5 Dc 0.12 12,000 4,000 0.20 8,500 4,300 0.25 6,000 4,000 0.30 5,000 4,200 SKD61,SKD11(1.2344,1.2379)6~8 Dc0.08 7,000 1,900 0.13 5,300 2,700 0.17 3,500 2,300 0.20 2,800 2,300 Below 255HB 9~11Dc 0.06 4,800 980 0.10 3,000 1,500 0.12 2,300 1,500 0.14 1,900 1,600 Hardened die steel Below5 Dc 0.10 9,600 2,900 0.18 6,300 2,800 0.22 4,700 2,800 0.27 2,200 1,600 SKD61,DAC,DHA(1.2344,1.2379)6~8 Dc0.074,800 1,400 0.11 3,000 1,300 0.15 2,300 1,400 0.18 1,900 1,400 40-50HRC 9~11Dc 0.05 4,000 700 0.09 2,600 1,100 0.10 1,900 1,100 0.12 1,500 1,100 Hardened die steel Below5Dc 0.10 4,800 1,300 0.16 3,000 1,200 0.20 2,300 1,200 0.24 1,900 1,200 SKD61,DAC,DHA(1.2344,1.2379)6~8 Dc0.064,000 980 0.10 2,600 1,000 0.13 1,900 1,000 0.16 1,500 1,000 55-60 HRC 9~11Dc 0.05 3,000 550 0.08 2,000 800 0.10 1,500 800 0.11 1,200 800 Grey & Nodular Below5 Dc 0.13 15,000 5,600 0.22 10,000 5,600 0.27 8,000 5,900 0.33 6,000 5,600 cast ironFC,FCD(GG,GGG)6~8 Dc0.09 8,700 1,900 0.14 5,800 3,200 0.16 4,300 3,200 0.22 3,500 3,200 Below 300HB 9~11Dc 0.07 5,600 1,200 0.11 3,700 2,000 0.13 2,700 2,000 0.15 2,200 2,000 L:Overhung length, Dc:Tool dia, ap: Depth of cut, n: Spindle speed, Vf: Feed speed Dimensions (mm) WorkMaterials L/Dc φ6×R1.5 φ8×R2 φ10×R1apnVfapnVfapnVf φ10×R2apn Vf (mm) (mm-1) (mm/min) (mm) (mm-1) (mm/min) (mm) (mm-1) (mm/min) (mm) (mm-1) (mm/min) Carbon steel Below5 Dc 0.37 4,800 4,800 0.50 3,500 4,700 0.25 2,800 4,700 0.50 2,800 4,700 S50C,S55C(C50,C55)6~8 Dc 0.25 2,300 2,300 0.34 1,700 2,300 0.17 1,400 2,300 0.34 1,400 2,300 Below 250HB 9~11Dc 0.18 1,500 1,500 0.24 1,100 1,400 0.12 900 1,500 0.24 900 1,500 Mold steel Below5 Dc 0.37 4,200 4,200 0.50 3,000 4,000 0.25 2,400 4,000 0.50 2,400 4,000 HPM7,NAK80,P20(1.2311)6~8 Dc 0.25 2,300 2,300 0.34 1,700 2,300 0.17 1,400 2,300 0.34 1,400 2,300 30-43 HRC 9~11Dc 0.18 1,500 1,500 0.24 1,100 1,400 0.12 900 1,500 0.24 900 1,500 Die steel Below5 Dc 0.37 4,200 4,200 0.50 3,000 4,000 0.25 2,400 4,000 0.50 2,400 4,000 SKD61,SKD11(1.2344,1.2379)6~8 Dc0.252,300 2,300 0.34 1,700 2,300 0.17 1,400 2,300 0.34 1,400 2,300 Below 255HB 9~11Dc 0.18 1,500 1,500 0.24 1,100 1,400 0.12 900 1,500 0.24 900 1,500 Hardened die steel Below5 Dc 0.33 1,800 1,600 0.45 1,300 1,500 0.20 1,900 2,900 0.45 1,900 2,900 SKD61,DAC,DHA(1.2344,1.2379)6~8 Dc0.221,500 1,300 0.30 1,100 1,300 0.15 900 1,300 0.30 900 1,300 40-50 HRC 9~11Dc 0.16 1,300 1,100 0.20 900 1,100 0.10 700 1,000 0.20 700 1,000 Hardened die steel Below5 Dc 0.30 1,500 1,200 0.40 1,100 1,100 0.20 900 1,200 0.40 900 1,200 SKD61,DAC,DHA(1.2344,1.2379)6~8 Dc0.201,300 1,000 0.27 900 900 0.13 700 900 0.27 700 900 55-60 HRC 9~11Dc 0.14 1,000 800 0.19 700 700 0.10 600 800 0.19 600 800 Grey & Nodular Below5 Dc 0.40 5,300 5,900 0.55 3,800 5,600 0.27 3,000 5,600 0.55 3,000 5,600 cast ironFC,FCD(GG,GGG)6~8 Dc0.272,900 3,200 0.37 2,100 3,100 0.16 1,700 3,100 0.37 1,700 3,100 Below 300HB 9~11Dc 0.20 1,800 2,000 0.26 1,300 1,900 0.13 1,000 1,800 0.26 1,000 1,800 L:Overhung length, Dc:Tool dia, ap: Depth of cut, n: Spindle speed, Vf: Feed speed D032

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском