Общий каталог Dijet 2018 - страница 416

Навигация

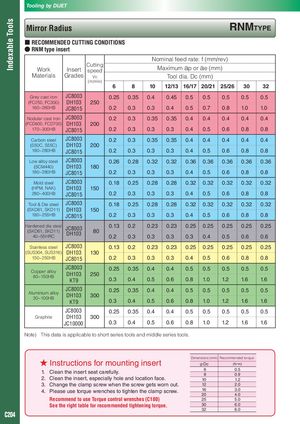

Indexable Tools Tooling by DIJET Mirror Radius RnMTyPE ■ RECOMMENDED CUTTING CONDITIONS ● RNM type insert Nominal feed rate: f (mm/rev) CuttingWorkInsertspeed Maximum ap or ae (mm) Materials Grades Vc Tool dia. Dc (mm) (m/min) 6 8 10 12/13 16/17 20/21 25/26 30 32 Grey cast iron JC8003 0.25 0.35 0.4 0.45 0.5 0.5 0.5 0.5 0.5 (FC250, FC300) DH103 250 160~260HB JC8015 0.2 0.3 0.3 0.4 0.5 0.7 0.8 1.0 1.0 Nodular cast iron JC8003 0.2 0.3 0.35 0.35 0.4 0.4 0.4 0.4 0.4 (FCD600, FCD700) DH103 200 170~300HB JC8015 0.2 0.3 0.3 0.3 0.4 0.5 0.6 0.8 0.8 Carbon steel JC8003 0.2 0.3 0.35 0.35 0.4 0.4 0.4 0.4 0.4 (S50C, S55C) DH103 200 180~280HB JC8015 0.2 0.3 0.3 0.3 0.4 0.5 0.6 0.8 0.8 Low alloy steel JC8003 0.26 0.28 0.32 0.32 0.36 0.36 0.36 0.36 0.36 (SCM440) DH103 180 180~280HB JC8015 0.2 0.3 0.3 0.3 0.4 0.5 0.6 0.8 0.8 Mold steel JC8003 0.18 0.25 0.28 0.28 0.32 0.32 0.32 0.32 0.32 (HPM, NAK) DH103 150 280~400HB JC8015 0.2 0.3 0.3 0.3 0.4 0.5 0.6 0.8 0.8 Tool & Die steel JC8003 0.18 0.25 0.28 0.28 0.32 0.32 0.32 0.32 0.32 (SKD61, SKD11) DH103 150 180~255HB JC8015 0.2 0.3 0.3 0.3 0.4 0.5 0.6 0.8 0.8 Hardened die steel(SKD61, SKD11)40~55HRCJC8003DH1030.130.2800.20.30.230.230.25 0.25 0.25 0.25 0.250.30.30.30.40.50.60.6 Stainless steel JC8003 0.13 0.2 0.23 0.23 0.25 0.25 0.25 0.25 0.25 (SUS304, SUS316) DH103 130 150~250HB JC8015 0.2 0.3 0.3 0.3 0.4 0.5 0.6 0.8 0.8 Copper alloy80~150HBJC8003DH103250KT9 0.25 0.35 0.40.30.40.50.40.60.5 0.50.81.0 0.51.2 0.51.6 0.51.6 JC8003Aluminium alloy30~100HBDH103KT93000.250.350.30.40.40.50.40.60.50.50.81.0 0.51.2 0.51.6 0.51.6 JC8003 0.25 0.35 0.4 0.4 0.5 0.5 0.5 0.5 0.5 Graphite DH103 300 JC10000 0.3 0.4 0.5 0.6 0.8 1.0 1.2 1.6 1.6 Note) This data is applicable to short series tools and middle series tools. Dimensions (mm) Recommended torque ★ Instructions for mounting insert φDc (N・m) 1. Clean the insert seat carefully. 6 0.580.9 2. Clean the insert, especially hole and location face. 10 1.2 3. Change the clamp screw when the screw gets worn out. 12 2.0 4. Please use torque wrenches to tighten the clamp screw. 16 3.0 20 4.0 Recommend to use Torque control wrenches (C180) 25 5.0 See the right table for recommended tightening torque. 30 6.0 32 6.0 C204

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском