Общий каталог Dijet 2018 - страница 417

Навигация

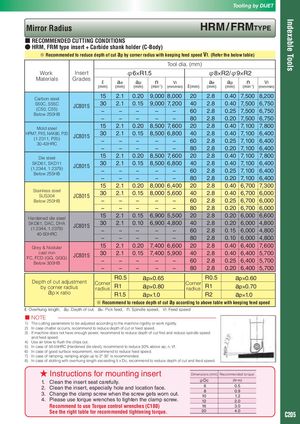

Indexable Tools Tooling by DIJET Mirror Radius HRM / FRMTyPE ■ RECOMMENDED CUTTING CONDITIONS ● HRM, FRM type insert + Carbide shank holder (C-Body) ※ Recommended to reduce depth of cut ap by corner radius with keeping feed speed Vf. (Refer the below table) Tool dia. (mm) Work Insert φ6×R1.5 φ8×R2/φ9×R2 Materials Grades ℓ ae ap n Vf ae ap n Vf (mm) (mm) (mm) (min-1) (mm/min) ℓ(mm) (mm) (mm) (min-1) (mm/min) Carbon steel 15 2.1 0.20 9,000 8,000 20 2.8 0.40 7, 500 8,200 S50C, S55C(C50, C55)Below 250HBJC8015 30 2.1 0.15 9,000 7, 200 40 2.8 0.40 7, 500 6,750−−−−−602.80.257, 5006,750 − − − − − 80 2.8 0.20 7, 500 6,750 Mold steel 15 2.1 0.20 8,500 7, 600 20 2.8 0.40 7, 100 7, 800 HPM7, PX5, NAK80, P20(1.2311, P20)JC801530-43HRC30−2.1 0.15 8,500 6,800 40−−−−60 2.82.8 0.40 7, 100 6,4000.257, 1006,400 − − − − − 80 2.8 0.20 7, 100 6,400 Die steel 15 2.1 0.20 8,500 7, 600 20 2.8 0.40 7, 100 7, 800 SKD61, SKD11(1.2344, 1.2379)Below 255HBJC801530−2.1 0.15 8,500 6,800 40−−−−60 2.82.8 0.40 7, 100 6,4000.257, 1006,400 − − − − − 80 2.8 0.20 7, 100 6,400 15 2.1 0.20 8,000 6,400 20 2.8 0.40 6,700 7, 300 Stainless steelSUS304JC8015 30 2.1 0.15 8,000 5,600 40 2.8 0.40 6,700 6,000 Below 250HB − − − − − 60 2.8 0.25 6,700 6,000 − − − − − 80 2.8 0.20 6,700 6,000 Hardened die steel 15 2.1 0.15 6,900 5,500 20 2.8 0.20 6,000 6,600 SKD61, DAC, DHA(1.2344, 1.2379)JC801540-50HRC30−2.1 0.10 6,900 4,800 40−−−−60 2.82.8 0.20 6,000 4,8000.156,0004,800 − − − − − 80 2.8 0.10 6,000 4,800 Grey & Nodular 15 2.1 0.20 7, 400 6,600 20 2.8 0.40 6,400 7, 600 cast ironFC, FCD (GG, GGG)JC8015Below 300HB30−2.1 0.15 7, 400 5,900 40−−−−60 2.82.8 0.40 6,400 5,7000.256,4005,700 − − − − − 80 2.8 0.20 6,400 5,700 R0.5 ap×0.65 R0.5 ap×0.60 Depth of cut adjustmentby corner radiusap × ratioCornerradiusR1R1.5ap×0.80ap×1.0 CornerradiusR1R2 ap×0.70ap×1.0 ※ Recommend to reduce depth of cut ap according to above table with keeping feed speed ℓ: Overhung length, ap: Depth of cut, ae: Pick feed, n: Spindle speed, Vf: Feed speed ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or feed speed. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed and feed speed. 4) Use air blow to flush the chips out. 5) In case of 50-55HRC (Hardened die steel), recommend to reduce 30% above ap, n, Vf. 6) In case of good surface requirement, recommend to reduce feed speed. 7) In case of ramping, ramping angle up to 2° 30′is recommended. 8) In case of slotting with overhung length exceeding 5 x Dc, recommend to reduce depth of cut and feed speed. ★ Instructions for mounting insert Dimensions (mm) Recommended torque 1. Clean the insert seat carefully. φDc (N・m) 2. Clean the insert, especially hole and location face.3.Change the clamp screw when the screw gets worn out.6810 0.50.91.2 4. Please use torque wrenches to tighten the clamp screw. 12 2.0 Recommend to use Torque control wrenches (C180) 16 3.0 See the right table for recommended tightening torque. 20 4.0 C205

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском