Общий каталог Dijet 2018 - страница 415

Навигация

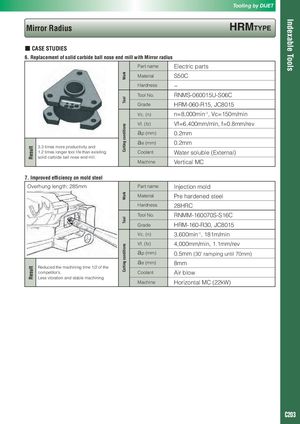

Indexable Tools ResultResult WorkToolCutting conditionsWorkToolCutting conditions Tooling by DIJET Mirror Radius HRMTyPE ■ CASE STUDIES 6. Replacement of solid carbide ball nose end mill with Mirror radius Part name Electric parts Material S50C Hardness − Tool No. RNMS-060015U-S06C Grade HRM-060-R15, JC8015 Vc, (n) n=8,000min-1, Vc=150m/min Vf, (fz) Vf=6,400mm/min, f=0.8mm/rev ap (mm) 0.2mm ae (mm) 0.2mm 3.3 times more productivity and 1.2 times longer tool life than exisiting Coolant Water soluble (External) solid carbide ball nose end mill. Machine Vertical MC 7. Improved efficiency on mold steel Overhung length: 285mm Part name Injection mold Material Pre hardened steel Hardness 28HRC Tool No. RNMM-160070S-S16C Grade HRM-160-R30, JC8015 Vc, (n) 3,600min-1, 181m/min Vf, (fz) 4,000mm/min, 1.1mm/rev ap (mm) 0.5mm (30’ ramping until 70mm) ae (mm) 8mm Reduced the machining time 1/2 of the competitor’s. Coolant Air blow Less vibration and stable machining Machine Horizontal MC (22kW) C203

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском