Общий каталог Dijet 2018 - страница 414

Навигация

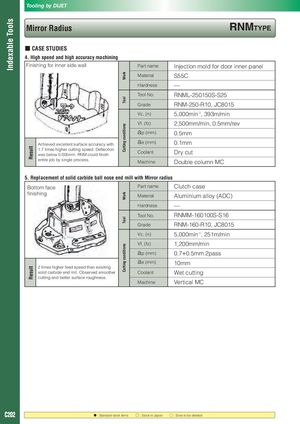

Indexable Tools ResultResult WorkToolCutting conditionsWorkToolCutting conditions Tooling by DIJET Mirror Radius RnMTyPE ■ CASE STUDIES 4. High speed and high accuracy machining Finishing for inner side wall Part name Injection mold for door inner panel Material S55C Hardness — Tool No. RNML-250150S-S25 Grade RNM-250-R10, JC8015 Vc, (n) 5,000min-1, 393m/min Vf, (fz) 2,500mm/min, 0.5mm/rev ap (mm) 0.5mm Achieved excellent surface accuracy with ae (mm) 0.1mm 1.7 times higher cutting speed. Deflectionwas below 0.005mm. RNM could finishCoolant Dry cut entire job by single process. Machine Double column MC 5. Replacement of solid carbide ball nose end mill with Mirror radius Bottom face Part name Clutch case finishing Material Aluminium alloy (ADC) Hardness — Tool No. RNMM-160100S-S16 Grade RNM-160-R10, JC8015 Vc, (n) 5,000min-1, 251m/min Vf, (fz) 1,200mm/min ap (mm) 0.7+0.5mm 2pass ae (mm) 10mm 2 times higher feed speed than exisiting solid carbide end mill. Observed smoother Coolant Wet cutting cutting and better surface roughness. Machine Vertical MC C202 : Standard stock items □ : Stock in Japan ○ : Soon to be deleted

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском