Общий каталог Dijet 2018 - страница 413

Навигация

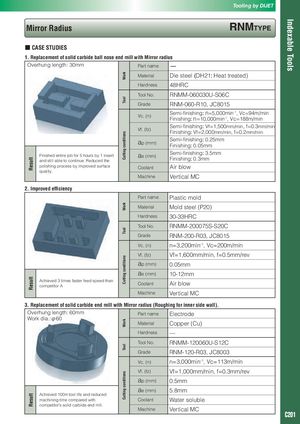

Indexable Tools ResultResultResult WorkToolCutting conditionsWorkToolCutting conditionsWorkToolCutting conditions Tooling by DIJET Mirror Radius RnMTyPE ■ CASE STUDIES 1. Replacement of solid carbide ball nose end mill with Mirror radius Overhung length: 30mm Part name Material Die steel (DH21: Heat treated) Hardness 48HRC Tool No. RNMM-060030U-S06C Grade RNM-060-R10, JC8015 Vc, (n) Semi-finishing: n=5,000min-1, Vc=94m/minFinishing: n=10,000min-1, Vc=188m/min Vf, (fz) Semi-finishing: Vf=1,500mm/min, f=0.3mm/minFinishing: Vf=2,000mm/min, f=0.2mm/min ap (mm) Semi-finishing: 0.25mmFinishing: 0.05mm Finished entire job for 5 hours by 1 insertand still able to continue. Reduced theae (mm)Semi-finishing: 3.5mmFinishing: 0.3mm polishing process by improved surface Coolant Air blow quality. Machine Vertical MC 2. Improved efficiency Part name Plastic mold Material Mold steel (P20) Hardness 30-33HRC Tool No. RNMM-200075S-S20C Grade RNM-200-R03, JC8015 Vc, (n) n=3,200min-1, Vc=200m/min Vf, (fz) Vf=1,600mm/min, f=0.5mm/rev ap (mm) 0.05mm ae (mm) 10-12mm Achieved 3 times faster feed speed thancompetitor A Coolant Air blow Machine Vertical MC 3. Replacement of solid carbide end mill with Mirror radius (Roughing for inner side wall). Overhung length: 60mm Part name Electrode Work dia.:φ60 Material Copper (Cu) Hardness — Tool No. RNMM-120060U-S12C Grade RNM-120-R03, JC8003 Vc, (n) n=3,000min-1, Vc=113m/min Vf, (fz) Vf=1,000mm/min, f=0.3mm/rev ap (mm) 0.5mm ae (mm) 5.8mm Achieved 100m tool life and reduced machining time compared with Coolant Water soluble competitor’s solid carbide end mill. Machine Vertical MC C201

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском