Общий каталог Dijet 2018 - страница 411

Навигация

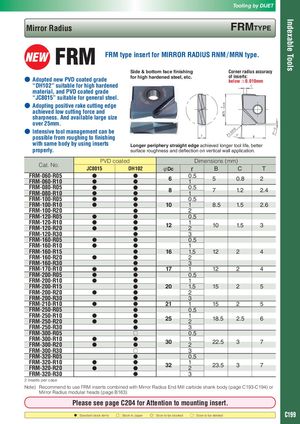

Indexable Tools 0 −0.020 3°〜5° Tooling by DIJET Mirror Radius FRMTyPE FRM FRM type insert for MIRROR RADIUS RNM / MRN type. Side & bottom face finishing Corner radius accuracy ● Adopted new PVD coated grade for high hardened steel, etc. of inserts:below ±0.010mm “DH102” suitable for high hardened C material, and PVD coated grade “JC8015” suitable for general steel. ● Adopting positive rake cutting edge achieved low cutting force and sharpness. And available large size over 25mm. ● Intensive tool management can bepossible from roughing to finishing T ±0.0103° B with same body by using inserts Longer periphery straight edge achieved longer tool life, better properly. surface roughness and deflection on vertical wall application. PVD coated Dimensions (mm) Cat. No. JC8015 DH102 φDc r B C T FRM-060-R05 ●FRM-060-R10● ●● 6 0.51 5 0.8 2 FRM-080-R05 ●FRM-080-R10● ●● 8 0.51 7 1.2 2.4 FRM-100-R05 ● ● 0.5 FRM-100-R10 ● ● 10 1 8.5 1.5 2.6 FRM-100-R20 ● 2 FRM-120-R05 ● ● 0.5 FRM-120-R10 ●FRM-120-R20● ●● 12 12 10 1.5 3 FRM-120-R30 ● 3 FRM-160-R05 ● ● 0.5 FRM-160-R10 ● ● 1 FRM-160-R15 ● 16 1.5 12 2 4 FRM-160-R20 ● ● 2 FRM-160-R30 ● 3 FRM-170-R10 ● ● 17 1 12 2 4 FRM-200-R05 ● ● 0.5 FRM-200-R10 ● ● 1 FRM-200-R15 ● 20 1.5 15 2 5 FRM-200-R20 ● ● 2 FRM-200-R30 ● 3 FRM-210-R10 ● ● 21 1 15 2 5 FRM-250-R05 ● 0.5 FRM-250-R10 ●FRM-250-R20● ●● 25 12 18.5 2.5 6 FRM-250-R30 ● 3 FRM-300-R05 □ 0.5 FRM-300-R10 ●FRM-300-R20● ●● 30 12 22.5 3 7 FRM-300-R30 □ 3 FRM-320-R05 ● 0.5 FRM-320-R10 ●FRM-320-R20● ●● 32 12 23.5 3 7 FRM-320-R30 ● 3 2 inserts per case Note) Recommend to use FRM inserts combined with Mirror Radius End Mill carbide shank body (page C193-C194) or Mirror Radius modular heads (page B163). Please see page C204 for Attention to mounting insert. : Standard stock items □ : Stock in Japan ◎ : Soon to be stocked ○ : Soon to be deleted C199

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском