Общий каталог Dijet 2018 - страница 378

Навигация

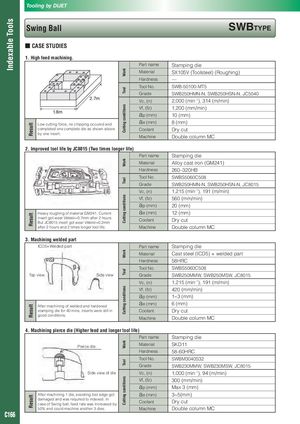

Indexable Tools ResultResultResultResult WorkToolCutting conditionsWorkToolCutting conditionsWorkToolCutting conditionsWorkToolCutting conditions Tooling by DIJET Swing Ball SWBTyPE ■ CASE STUDIES 1. High feed machining. Part name Stamping die Material SX105V (Toolsteel) (Roughing) Hardness — Tool No. SWB-50100-MT5 Grade SWB250HMN-N, SWB250HSN-N, JC5040 2.7m Vc, (n) 2,000 (min-1), 314 (m/min) Vf, (fz) 1,200 (mm/min) 1.8m ap (mm) 10 (mm) Low cutting force, no chipping occured and ae (mm) 8 (mm) completed one complete die as shown above Coolant Dry cut by one insert. Machine Double column MC 2. Improved tool life by JC8015 (Two times longer life) Part name Stamping die Material Alloy cast iron (GM241) Hardness 260–320HB Tool No. SWBS5060C508 Grade SWB250HMN-N, SWB250HSN-N, JC8015 Vc, (n) 1,215 (min-1), 191 (m/min) Vf, (fz) 560 (mm/min) ap (mm) 20 (mm) Heavy roughing of material GM241. Current ae (mm) 12 (mm) insert got wear VBMAX=0.7mm after 2 hours.But JC8015 insert got wear VBMAX=0.2mmCoolant Dry cut after 2 hours and 2 times longer tool life. Machine Double column MC 3. Machining welded part ICD5+Welded part Part name Stamping die Material Cast steel (ICD5) + welded part Hardness 58HRC Tool No. SWBS5060C508 Top view Side view Grade SWB250MMW, SWB250MSW, JC8015 Vc, (n) 1,215 (min-1), 191 (m/min) Vf, (fz) 420 (mm/min) ap (mm) 1~3 (mm) After machining of welded and hardened ae (mm) 6 (mm) stamping die for 40 mins, inserts were still in Coolant Dry cut good conditions. Machine Double column MC 4. Machining pierce die (Higher feed and longer tool life) Part name Stamping die Pierce die Material SKD11 Hardness 58-60HRC Tool No. SWBM3040S32 Grade SWB230MMW, SWB230MSW, JC8015 Side view of die Vc, (n) 1,000 (min-1), 94 (m/min) Vf, (fz) 300 (mm/min) ap (mm) Max 3 (mm) After machining 1 die, exsisting tool edge got ae (mm) 3~5(mm) damaged and was required to indexed. Incase of Swing ball, feed rate was increased byCoolantDry cut 50% and could machine another 3 dies. Machine Double column MC C166

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском