Общий каталог Dijet 2018 - страница 362

Навигация

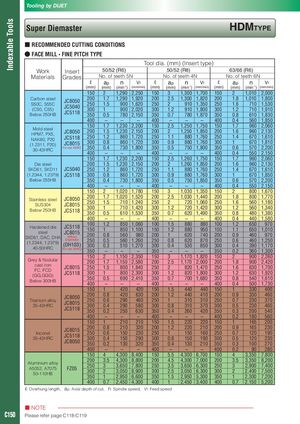

Indexable Tools Tooling by DIJET Super Diemaster HDMTyPE ■ RECOMMENDED CUTTING CONDITIONS ● FACE MILL • FINE PITCH TYPE Tool dia. (mm) (Insert type) Work Insert 50/52 (R6) 50/52 (R8) 63/66 (R6) Materials Grades No. of teeth 5N No. of teeth 4N No. of teeth 6N ℓ ap n Vf ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) 150 2 1,290 2,250 150 3 1,300 1,700 150 2 1,010 2,000 Carbon steelS50C, S55C(C50, C55)Below 250HBJC8050JC5040JC51182002503003501.71,2901,9201.59001,62019002,0200.57802,1502002503003502.51,3001,82020029101,3502501.29101,8003000.77801,8703501.81,0101,8001.67101,5301.27101,9100.86101,830 400 – – – 400 – – – 400 0.4 560 1,850 150 1.7 1,230 2,200 150 2.5 1,250 1,750 150 1.7 960 2,060 Mold steelHPM7, PX5,NAK80, P20(1.2311, P20)30-43HRCJC8050JC5118JC8015For over 40HRC2002503003504001.51,2302,1501.28601,7200.88601,7200.47301,800–––20025030035040021,2501,8502001.18801,7602500.98801,7603000.57501,800350–––4001.61.410.60.49602,1306701,6106701,8105702,2005502,150 150 1.7 1,230 2,200 150 2.5 1,260 1,750 150 1.7 960 2,060 Die steel 200 1.5 1,230 2,150 200 2 1,260 1,850 200 1.6 960 2,130 SKD61, SKD11 JC5040 250 1.2 860 1,720 250 1.1 880 1,760 250 1.4 670 1,610 (1.2344, 1.2379) JC5118 300 0.8 860 1,720 300 0.9 880 1,760 300 1 670 1,850 Below 255HB 350 0.4 730 1,800 350 0.5 750 1,850 350 0.6 570 2,200 400 – – – 400 – – – 400 0.4 550 2,150 150 2 1,020 1,780 150 3 1,030 1,350 150 2 800 1,670 Stainless steelSUS304Below 250HBJC8050JC8015JC51182002503003501.71,0201,5201.57101,24017101,4200.56101,5302002503003502.51,0301,44020027201,0602501.27201,4203000.76201,4903501.81.61.20.88001,7705601,1805601,3404801,380 400 – – – 400 – – – 400 0.4 440 1,580 Hardened die JC5118steelJC8015SKD61, DAC, DHAWithoutChipbreaker(1.2344, 1.2379)(DH103)40-50HRC(For over 50HRC)1001502002503003501.210.80.50.3–8501,0601001.58501,1001501.256098020015601,2602500.85101,2703000.4––350–880880100880950150620740200620870250530850300––3501.21.10.90.60.40.26509706501,0104609704601,2503901,1703601,300 150 2 1,150 2,350 150 3 1,170 1,820 150 2 900 2,260 Grey & Nodularcast ironFC, FCD(GG,GGG)JC8015JC5118Below 300HB2002503003504001.71,1502,5801.58001,84018002,3000.56902,410–––2002503003504002.51,1702,00020028201,4702501.28201,8003000.77001,680350–––4001.81.61.20.80.49002,4206301,7006301,9205401,6105001,730 150 1 420 420 150 1.5 440 440 150 1 330 400 Titanium alloy35-43HRCJC8050JC8015JC5118 2002503003500.80.60.40.2420630 200 1.229046025012905803000.82506303500.44404102003103102503103703002604203500.90.70.50.3330460230370230460200540 400 – – – 400 – – – 400 0.2 180 560 150 1 210 210 150 1.5 220 220 150 1 165 200 Inconel35-43HRCJC8015JC5118JC8050 2002503003500.80.60.40.2210320 200 1.215023025011502903000.81303203500.42202102001501602501501903001302103500.90.70.50.3165230120190120230100270 400 – – – 400 – – – 400 0.2 90 280 150 4 4,300 8,400 150 5.5 4,300 6,700 150 4 3,350 7,800 Aluminium alloyA5052, A7075FZ0550-110HB 200 3.5 4,300 8,800 200 4.5 4,300 7,000 20025033,6507,8002503.53,6506,30025030023,0508,9003002.53,0506,30030035012,9506,6003501.52,9505,3003503.53,3508,20032,9007,40022,4007,50012,3007,200 400 0.7 2,450 4,300 400 1 2,450 3,400 400 0.7 2,150 5,200 ℓ: Overhung length, ap: Axial depth of cut, n: Spindle speed, Vf: Feed speed ■ NOTE C150 Please refer page C118-C119

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском