Общий каталог Dijet 2018 - страница 361

Навигация

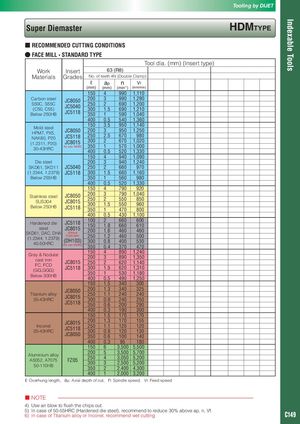

Indexable Tools Tooling by DIJET Super Diemaster HDMTyPE ■ RECOMMENDED CUTTING CONDITIONS ● FACE MILL • STANDARD TYPE Tool dia. (mm) (Insert type) Work Insert 63 (R8) Materials Grades No. of teeth 4N (Double Clamp) ℓ ap n Vf (mm) (mm) (min-1) (mm/min) 150 4 990 1,110 Carbon steelS50C, S55C(C50, C55)Below 250HBJC8050JC5040JC5118200250300350321.519901,2906901,2006901,2105901,040 400 0.5 540 1,360 Mold steelHPM7, PX5,NAK80, P20(1.2311, P20)30-43HRC150JC8050200JC5118250JC8015300For over 40HRC3504003.532.5210.59501,1409501,2506709806701,0205701,0005201,330 150 4 940 1,090 Die steel 200 3 940 1,240 SKD61, SKD11 JC5040 250 2 660 970 (1.2344, 1.2379) JC5118 300 1.5 660 1,160 Below 255HB 350 1 560 980 400 0.5 520 1,330 150 4 790 920 Stainless steelSUS304Below 250HBJC8050JC8015JC5118200250300350321.517901,040550850550960470800 400 0.5 430 1,100 Hardened die JC5118steelJC8015SKD61, DAC, DHAWithout(1.2344, 1.2379)40-50HRCChipbreaker(DH103)(For over 50HRC)10015020025030035021.81.61.20.80.4660660460460400370600610460500530470 Grey & Nodularcast ironFC, FCD(GG,GGG)JC8015JC5118Below 300HB1502002503003504004321.510.58901,2408901,3506201,1406201,3105301,1804901,250 150 1.5 340 300 Titanium alloy35-43HRCJC8050JC8015JC5118 2002503003501.31.10.90.6340240240200325240250290 400 0.3 190 300 150 1.5 170 170 Inconel35-43HRC JC8015JC5118JC8050 2002503003501.31.10.90.6170120120100155120130140 400 0.3 95 180 150 6 3,500 5,500 Aluminium alloyA5052, A7075FZ0550-110HB 200 52504300335023,5005,7003,0505,2002,5005,2002,4004,300 400 1 2,000 3,200 ℓ: Overhung length, ap: Axial depth of cut, n: Spindle speed, Vf: Feed speed ■ NOTE 4) Use air blow to flush the chips out. 5) In case of 50-55HRC (Hardened die steel), recommend to reduce 30% above ap, n, Vf.6)In case of Titanium alloy or Inconel, recommend wet cuttingC149

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском